| Place of origin: | China |

| MOQ: | 1 set |

| Production capacity : | 3000-3200sets/Month |

| Delivery time: | 5 days generally after getting the official PO |

| Package: | Per set packed with a box and then put all in the plywood case f |

| Certificate: | Industry Standard |

| Material: | G10, phonemic, G11, Mylar, |

| Feature | Isolation Kits are mainly used for electrical flange insulation |

| Usage: | Insulation kits are usually used in places where electrical corrosion protection and electrical insulation are required, such as offshore equipment, seawater environments, chemical equipment, and oil refinery pipeline |

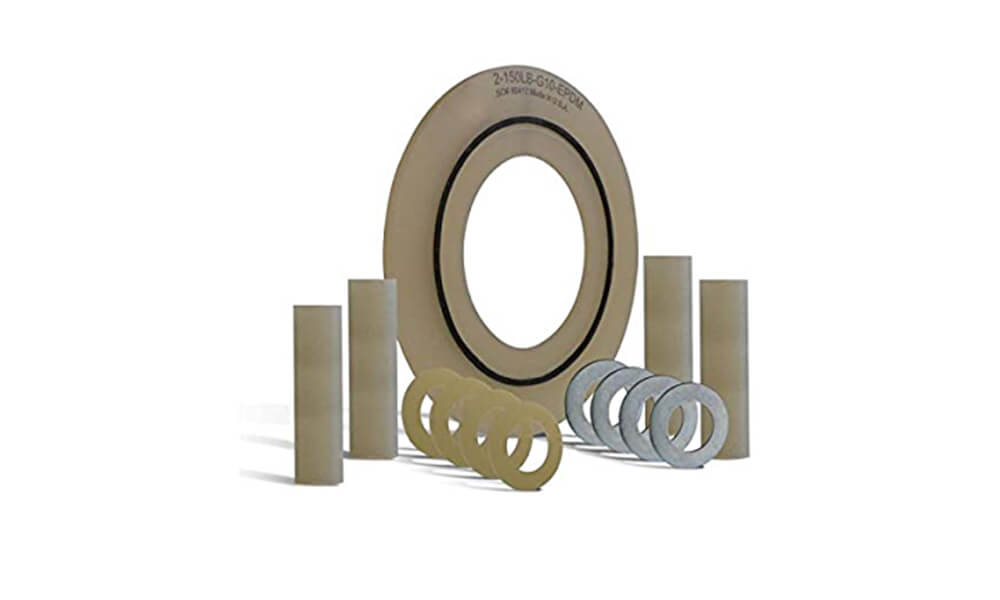

Longseal supplies three standard types flange insulation kit; designed to fit any raised end face, flat end face or ring groove flange assembly. Each kit includes HDS 1 flange insulating gasket and the following:

- Choose G11 or polyester film for sleeves.

- Two HDS-1 washers per bolt

- Two plated steel washers per bolt

- Sleeves choose G11 or polyester film

Insulation Gasket Kits Specification

| Property | Plain Phenolic |

Neo-faced Phenolic |

Silicone Glass G-7* |

Epoxy Glass G-10 |

Epoxy Glass G-11 |

| Dielectric strengths, Volts/mil |

500 | 500 | 350-400 | 550 | 550 |

| Compressive strength, psi |

25,000 | 25,000 | 40,000 | 50,000 | 50,000+ |

| Water absorption, % | 1.6 | 1.6 | 0.07 | 0.10 | 0.10 |

| Insulating Resistance, Meg Ohms |

40,000 | 40,000 | 2,500 | 200,000 | 200,000 |

| Flexural strength, psi | 22,500 | 22,500 | 27,000 | 45,000 | 43,000 |

| Operating temp, ºF | -65 to +220 | -65 to +175 | -292 to +450 | -292 to +280 | -292 to +350 |

| Operating temp, ºC | -54 to +104 | -54 to +79 | -180 to +232 | -180 to +138 | -180 to +177 |

* = G-7 material should not be used with hydrocarbons, not even trace amounts.

| Material | Dielectric Strength | Water Ab-sorption | Maximum Temperature | |

| Mylar | 4000 vpm | .8% | 300°F | 149°C |

| Integral Minlon | 1200 vpm | .22% | 200°F | 93°C |

| Polyethylene | 400 vpm | .01% | 105°F | 41°C |

| Phenolic | 400p vpm | 2% | 225°F | 107°C |

| G-10 | 550 vpm | .10% | 285°F | 141°C |

| Nomex | 400 vpm | n/a | 450°F | 232°C |

| Material | Dielectric Strength | Water Ab-sorption | Compressive Strength | Maximum Temperature | |

| Plain Faced Phenolic | 500 vpm | 1.50% | 25 000 psi | 225 °F | 107°C |

| Neoprene Faced Phenolic | 500 vpm | 1.50% | 25 000 psi | 175 °F | 79°C |

| G-10 | 550 vpm | .10% | 50 000 psi | 285°F | 141°C |

| Special & High Temperature: Available upon request | |||||

| Material | Dielectric Strength | Water Ab-sorption | Compressive Strength | Maximum Temperature | |

| Phenolic | 400 vpm | 1.10% | 25 000 psi | 225 °F | 107°C |

| G-10 | 550 vpm | .10% | 50 000 psi | 285°F | 141°C |

| Special & High Temperature: Available upon request | |||||

Insulation Gasket Kits Supplier FAQ

Flange Insulation Kits – Definitive Guide

Longseal flange insulation kits are usually used in places where electrical corrosion protection and electrical insulation are required, such as offshore equipment, seawater environments, chemical equipment, and oil refinery pipelines. Longseal flange insulation kit is specially designed for electrical flange insulation. They are used as insulators between different metal flanges or electrical isolation parts in pipes Cathodic protection system prevents static electricity from flowing along the pipeline.

1. What is a flange insulation gasket kit?

The most common problem in piping/piping system design is flanges. Therefore, we must double to ensure that the seal is correct to prevent flange leakage. At the same time, it must be cathodic insulated to prevent stray currents, which are considered inappropriate corrosion and final metal breakdown. Insulating gasket sets or flange insulation kits play an important role in this situation.

- Used for flange electrical insulation.

- Metal flanges are insulated from each other by these plates.

- In addition, they are used in the electrical isolation part of the pipeline (different metal) in the cathodic protection system; thereby preventing the electrostatic charge from flowing along the pipeline, because they eliminate the possibility of the galvanic battery system.

2. Main application of insulating gasket kit

Insulating gasket kits can be used in all places where galvanic corrosion protection and electrical insulation are required. Commonly used applications include pipelines/pipe systems in seawater environments, offshore facilities, chemical facilities, and refinery pipelines.

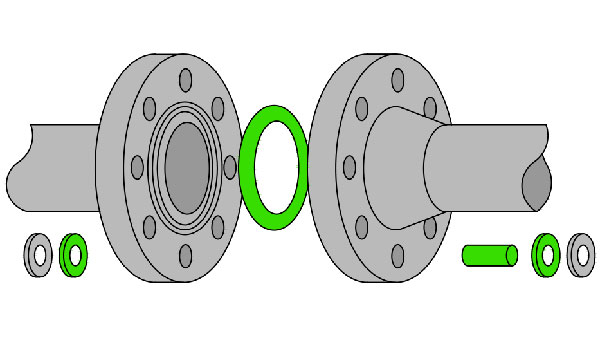

3. Flange Insulation Gasket Components

Each flange insulation gasket composed of

- A central plane or oval part gasket,

- One insulating sleeve per bolt

- Each bolt and two insulating steel gaskets

- Two plated steel gaskets per bolt.

All these parts are produced using special materials with chemical stability, dielectric properties and low water absorption, thus solving this problem. The complete set of equipment is individually packaged, and the flange size, rating, type and material combination are clearly indicated on the label. Insulation kits are usually available up to 24 inches but customized higher nominal sizes can be produced on request.

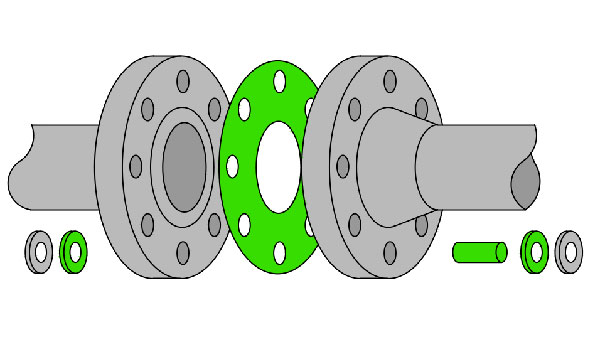

4. Assemble the flange insulation gasket components

Polyethene insulating sleeves and mounting studs are the main components of the insulating gasket kit. Contrary to the conventional nut and bolt system for flange connection, the insulating assembly uses studs with gaskets and nuts at both ends of the flange connection. The insulating sleeve is then inserted into the bolt hole using the insulators on both sides of the flange. Therefore, two insulator flanges are inserted into each bolt hole. Then insert the installation stud into the insulating sleeve until the threads at both ends of the stud are visible outside the flange. A flat steel gasket is slid to each end of the stud, and a nut is threaded to each end of the stud and tightened.

The flange insulation assembly becomes stronger when both nuts at each end of the stud are tightened. In the traditional way of tightening bolts with nuts, all the clamping force is applied to a set of threaded stud bolts, such as flange insulation tools, and the clamping force is evenly divided among the threads in each end of the stud as well as the nut. The stud is to protect and insulate any charge and corrosion. This forms a flange connection that will not corrode or fail due to the chemical reaction between two different metals.

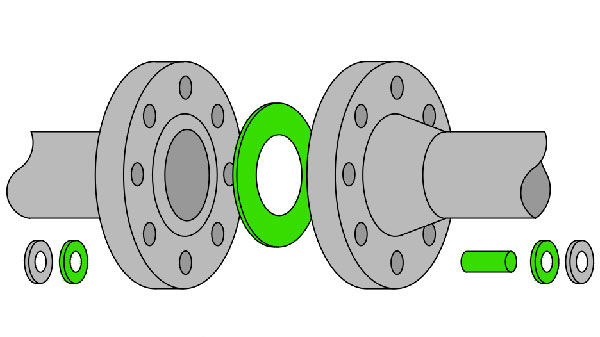

5. Types of flange insulating gaskets

There are four main types of gasket isolation components on the market, which are designated F, E, D and o. Each type of flange assembly is suitable for flanges and specific types of flange surfaces (RF, FF, RTJ).

1) F type gasket

The production of F-type gaskets is suitable for raised face flanges. The inner diameter of the bolt hole circle is made slightly smaller than the outer diameter of the gasket to ensure the automatic positioning of the gasket. In order to avoid the accumulation of foreign matter, a special belt protection device can be used to further strengthen the cathode isolation. These are made of 1/8″ thick fibre phenolic board, either uncoated or coated with nitrile rubber on both sides. F-type gaskets can also be made of non-asbestos fibres and have high isolation.

2) E type gasket

In the full type, “E” type gasket, the outer diameter of the gasket matches the outer diameter of the flange. So the gasket completely covers the entire flange surface. With precision positioning bolt holes, it is easy to locate in the centre. This design will prevent foreign matter from accumulating between the flange surfaces, thereby enhancing the isolation performance of the components. E-type flange insulation components can be phenolic, neoprene-faced phenolic and high-temperature materials.

3) D type gasket

The “D” type gasket is suitable for the annular groove of the RTJ flange (style R, RX, and BX). They are available in medium woven reinforced phenolic and other materials, the size meets ANSI standards, and there are basic oval and octagonal shapes. This kind of gasket is called “API ring joint”.

4) O type gasket

O-rings are special because they have additional sealing elements on both sides of the device, usually, Teflon, Nitrile or Viton rubber, and can be used in rings and full designs (E-type and F-type).

6. Insulating gasket material

- All materials should be selected to ensure long-term effective sealing and electrical insulation of the flange connection.

- In order to take advantage of the best characteristics, sometimes the gasket is made of a combination of materials.

Common gasket materials include G3, G7, nitrile surface, common phenolic, G10, chloroprene phenolic, Klinger, Teflon, Deron, etc. Popular sleeve materials are phenolic, polyester film, polyethene, Minion, or Nomex. Common gasket materials are phenolic, steel, G7, G3 or G10, which can be used as a single gasket and sleeve kit, one-piece gasket kit, double gasket kit or one-piece double gasket kit (Minlon)

7. Sleeve and washers of flange insulating gasket kits

1) One-piece sleeve and gasket

One-piece sleeves and gaskets can be molded with acetal resin. They should generally be used as a single gasket group because they are formed to a specific length and in many cases are longer than the thickness of a single flange. They can be used for bolt diameters from ½” to 1-1/2″ (12.7 mm to 38.1 mm), and are limited to applications where the flange temperature does not exceed +180^ of (+80^oC).

A special feature is the gasket centring ring, which correctly positions the steel gasket on the unit to avoid uneven pressure on the gasket.

2) Insulating gasket

The standard insulating gasket is made of high-strength phenolic aldehyde, which provides tough positive insulation at a temperature of +300^ of (+150^oC). They can be used for bolt sizes from ½” (12.7 mm) to 3½” (88.9 mm), and are made to fit in insulating sleeves. Glass fiber reinforced high temperature phenolic insulating gaskets can provide standard insulating gaskets of the same size according to special orders

3) Insulated sleeves

Insulating sleeves can be made of polyester film, polyethene, phenolic, and Nomex. The flange bolts are through 3-1/2″ (88.9mm) and can be installed easily over standard bolt sizes, even if misaligned. Insulating sleeves together with separate insulating gaskets For use, the standard wall thickness is 1/32″ (0.79 mm). They can be used for standard American bolt sizes from ½” (12.7 mm) to 3½” (88.9 mm), as well as metric bolt sizes from 12 mm and larger.

4) Steel gasket

Steel gaskets are designed to be installed on retaining rings on insulating sleeves or integral sleeves and gaskets. The outer diameter size is suitable for the bolt face on ANSI standard flange. They are made from hot rolled steel plates with an 1/8″ (3.2 mm) thickness. Pyro insulating sleeves and gaskets are also available.

8. Flange insulating gasket assembly installation procedure

Gaskets usually have an inner diameter a little smaller than those found on flanges. When installing, make sure the gasket is properly centered on the hole. It can prevent the accumulation of foreign matter between the flange faces during the pigging process.

A single gasket insulation sleeve is recommended for underground flanges. This should be installed on the unprotected side of the flange, which will provide cathodic protection for the studs and nuts. For above-ground flanges, it is recommended to use double gaskets to facilitate testing.

It is always recommended to use positioning pins to ensure the proper alignment of flanges and gaskets. The size of each pin is at least 3/32″ (2.38 mm) larger than the bolt.

A schematic diagram showing the recommended bolt tightening sequence is usually provided with each insulating gasket set.

9. General supplier of insulating gasket kits

Common suppliers that produce and supply insulating gaskets are

- PSI

- Pikotek

- Central Plastics

- Garlock

- Longseal

- Trojan

- Lemons

- Advance Products and Systems

10. Information required to order flange insulation kits

To order an insulating gasket kit, you need to provide the following information:

- Flange specifications (ANSI/ASME, DIN, API, MSS SP44, BSI, AWWA standards)

- Nominal pipe size, pressure rating, inner diameter size

- Operating pressure, temperature and medium

- Gasket type (D/E/F/O)

- Sealing material requirements

- Isolation casing material

- Isolating gasket material

- Metal gasket material

- quantity