In the production processes of the petroleum, chemical, and pharmaceutical industries, equipment such as pipelines, valves, and pressure vessels is interconnected through passages. To prevent leakage at every flange joint, a sealing gasket is typically placed. However, because these applications often involve sealing high-temperature or corrosive gases and liquids, traditional gasket materials may not be sufficient. Polytetrafluoroethylene (PTFE) offers a solution, as it combines high-temperature resistance, aging resistance, and excellent chemical inertness, making it a superior choice for sealing gaskets in such environments.

Pure molded PTFE gaskets suffer from poor elastic recovery, which seriously compromises sealing performance. To overcome this drawback, we developed the expanded PTFE (ePTFE) gasket. This article describes a detailed preparation process for an enhanced ePTFE gasket that not only improves recovery but also enhances the sealing reliability of the joint.

A Manufacturing Method — Layer-Laminated ePTFE Gasket

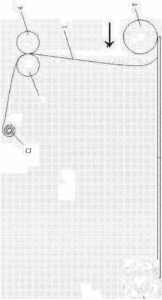

A selected roll of ePTFE microporous film is mounted on an unwinder. The leading edge of the film passes through the gap between the left and right traction rollers. With the assistance of these rollers, the film makes contact with a horizontal working platform. The left and right traction rollers, along with a pressure roller mounted at either the left or right end of the platform, move back and forth in unison. The roller pressure is set between 0.5 and 2 MPa, and the roller temperature is maintained at 150 to 250 °C, allowing the ePTFE film to be repeatedly calendered flat and stacked on the platform.

After each layer is laid down, an adhesive is uniformly sprayed on the upper surface to bond the next layer. This process continues until the desired thickness is achieved. Once completed, the laminate is allowed to rest on the platform for 24 hours at a temperature of 50 to 150 °C. Finally, the edges are trimmed to create the finished expanded PTFE sealing gasket.

Detailed Manufacturing Steps

Here is further described in detail with reference to the accompanying drawings of the ePTFE gasket manufacturing method.

(1) Selection of ePTFE Microporous Film

Roll length: 50–1000 m to ensure sufficient material for lamination to the required thickness.

Width: 1–2 m, chosen to suit the gasket size to be produced.

Film thickness: 5–50 μm, with uniform thickness.

Porosity: 30–80%.

(2) Lamination and Bonding

a. Unwinding and Tension Control

Mount the ePTFE film roll on an unwinder with a tension control system. Feed the film’s leading end through the gap between the left and right traction rollers. Apply appropriate tension via the roller nip pressure; adjust as needed so the film remains taut. Under traction, bring the film into contact with the horizontal working platform.

b. First Pass and Lower Layer Lay-Down

Move the left and right traction rollers and the left pressure roller (located at the left end of the platform) synchronously from left to right. The left pressure roller calenders and lays the lower ePTFE film layer flat on the platform. Return the left pressure roller to its initial position at the platform’s left end.

Set left pressure roller pressure to 0.5–2 MPa and roller temperature to 150–250 °C. Maintain the platform temperature at 50–150 °C to ensure full evaporation of the solvent in the adhesive to be sprayed.

c. Adhesive Application on Lower Layer

Uniformly spray adhesive onto the upper surface of the lower ePTFE film laid on the platform at 10–50 g/m². After spraying, stand for 5–10 minutes to allow the solvent to evaporate sufficiently.

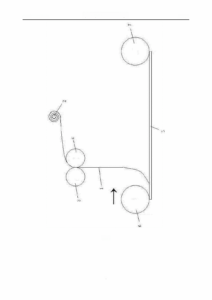

d. Second Pass and Upper Layer Lay-Down

Move the left and right traction rollers and the right pressure roller (at the right end of the platform) synchronously from right to left. The right pressure roller calenders and lays the upper ePTFE film layer flat onto the upper surface of the lower layer. Return the right pressure roller to its initial position at the platform’s right end.

Set the right roller pressure to 0.5–2 MPa and roller temperature to 150–250 °C. Maintain the platform temperature at 50–150 °C to ensure the adhesive solvent evaporates adequately, thereby bonding the upper film’s lower surface to the lower film’s upper surface.

e. Adhesive Application on the New Upper Layer

Uniformly spray adhesive onto the upper surface of the newly laid upper ePTFE film at 10–50 g/m². After spraying, stand for 5–10 minutes to allow solvent evaporation.

f. Third Pass and Next Layer Lay-Down

Move the left and right traction rollers and the left pressure roller synchronously from left to right. The left pressure roller calenders and lays the next ePTFE film layer onto the upper surface of the previously laid upper film. Return the left pressure roller to its initial position at the platform’s left end.

Set left pressure roller pressure to 0.5–2 MPa and roller temperature to 150–250 °C. Maintain the platform temperature at 50–150 °C to fully evaporate adhesive solvent, thereby bonding the next layer to the previous layer.

g. Repeat Stacking

Continue the lamination and bonding cycle—spraying adhesive, allowing flash-off, and calendering each layer—until the desired ePTFE gasket thickness is achieved.

h. Post-Lamination Conditioning and Finishing

Hold the platform temperature at 50–150 °C and stand for 24 hours to further remove any residual adhesive solvent remaining within the laminated ePTFE film layers. Then trim the edges to obtain the finished ePTFE sealing gasket.

Note: In the above operations, the temperatures of the left and right pressure rollers are set to the same value.

Remarks and Performance Results

This method utilizes lamination to manufacture expanded PTFE gaskets. The process involves layering calendered sheets flat on a horizontal platform and bonding them together using a sprayed adhesive. To ensure optimal results, it is essential to control the following parameters during operations: pressure should be maintained at 0.5–2 MPa, roller temperature at 150–250 °C, and platform temperature at 50–150 °C. After the lamination process, the platform should be kept at 50–150 °C for 24 hours to further remove any unevaporated adhesive solvents. The final steps involve edge removal and trimming to yield the completed product.

Using this laminated ePTFE method significantly improves the recovery rate of expanded PTFE gaskets. Inspection results from an authoritative Product Quality Supervision and Testing Center show the following performance metrics:

Compression rate: Standard requirement 45 ± 5 %; test result 48.5 %.

Recovery rate: Standard requirement ≥ 10 %; test result 12 %.

Additionally, the sealing performance is notably enhanced. Even when there are surface defects on the mating parts being sealed, the expanded PTFE gasket produced by this method maintains effective sealing. The gasket demonstrates good sealing performance, even on surfaces with minor imperfections.

This process and product are specifically designed for flanged connections in oil and gas, chemical processing, and pharmaceutical plants, where high temperatures and corrosive media necessitate a gasket that possesses the inherent chemical resistance of PTFE while also offering improved flexible recovery. By adopting the laminated expanded PTFE (ePTFE) gasket process described above, users can achieve more reliable sealing at pipe, valve, and vessel flanges in demanding applications.