| Place of origin: | China |

| MOQ: | 1 pcs |

| Production capacity : | 10000-1500pcs/Month |

| Delivery time: | 3-5 days generally after getting the official PO |

| Package: | Carton Or plywood case |

| Certificate: | Industry Standard |

| Material: | Non-asbestos, PTFE, asbestos, Rubber, Ceramic Fiber, Glass Fiber, Graphite, and so on |

| feature: | low-cost sealing material for pipe flange, pump, and valve joints. |

| Suitable for a variety of sealing requirements |

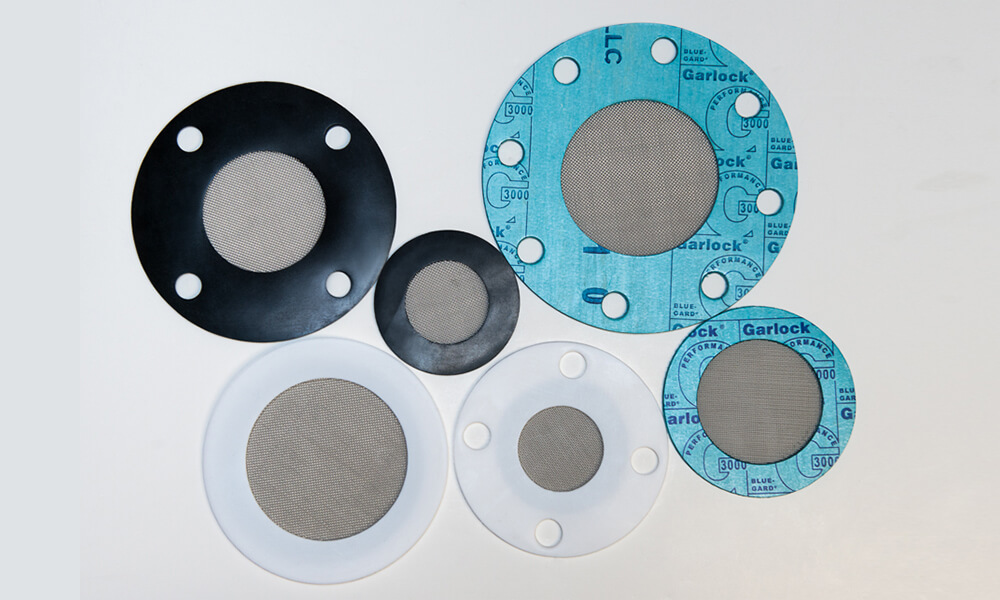

Regardless of the pressure level or temperature range of your application, Longseal has the right sealing solution for you. Our non-metallic gaskets are designed to meet the highest quality standards and are useful in low-pressure applications. As part of our strategy to provide customers with a wider range of sheet gasket products, we provide a variety of non-metal gasket materials, including elastomer and fiber gaskets, compressed non-asbestos gaskets, PTFE gaskets, and more.

- Wide Service Temperature Range

- Low to Moderate Pressures

- Severe Chemical Services

- Petroleum & Chemical Upstream, Midstream and Downstream

- Piping & Vessels

- Valves

- Pumps

PTFE Bonded EPDM Gasket

PTFE Bonded EPDM gasket is produced with high-quality EPDM rubber and PTFE for maximum chemical and corrosion resistance. They are suitable for fiberglass, glass-lined, and steel full-face flanges. The gaskets have Low bolt torque with superior sealing, Dual, Concentric, Convex sealing rings;

Insulation Gasket Kits

The Flange Insulation Gasket Kit is composed of insulating gasket, bot, sleeve, nut, insulatiing gasket and steel gasket; It is the most widely used form of controlling losses due to corrosion. Flange Insulation Gasket Kit can be used to control stray electric currents in piping at oil, gas, water, refinery, and chemical plants to increase the effectiveness of cathodic protection systems and confine or eliminate electrolytic corrosion.

Non Metallic Gasket Manufacturers FAQ

Non Metal Gasket – Definitive Guide

Gaskets, sometimes called seals, are materials used to seal two ring-shaped mating parts to make them leak-proof. These are usually used on the flanges of the matching pipelines of different fluids or pressure vessels to form a static seal, making it completely leak-proof under all working and weather conditions. A gasket is often divided into the metallic gasket and non-metallic gasket.

1. What is Non-Metallic Gasket

Non-metallic gaskets are usually made of composite sheet materials such as aramid fibre, glass fibre or polytetrafluoroethylene (PTFE), and are used in low-pressure applications together with flat flanges and raised face flanges. No metal is used in the construction process.

Common information includes:

- Two-way guide (filled) PTFE Gasket

- Flexible Graphite Sheet

- Mica slice

- Ceramic fiber

- Elastic and fiber sheet

Compressed non-asbestos board

- Expanded polytetrafluoroethylene board

- Glass filled/reprocessed PTFE sheet

All-round non-metallic gaskets, suitable for flat flanges; flat ring gaskets for raised face flanges. Non-metallic washers-also called soft washers-are easily compressed under bolt load. Because they are metal-free, they have excellent corrosion resistance, but can only handle a limited range of temperature and pressure.

The most common applications for non-metallic gaskets are pipeline flanges, heat exchangers, compressors, and bonnet valves. These washers are available in a variety of cutting shapes.

There are many types of non-metallic gaskets commonly used in the industrial sector. The following is the classification and application of non-metallic gaskets, as well as the advantages and disadvantages of each type of gasket.

2. Types of non-metallic gaskets

Common types of non-metallic gaskets include:

- Fiber Reinforced Gasket

- Graphite washers

- PTFE gasket

- Rubber gasket

1) Fiber Reinforced Gasket

The fibre-reinforced gasket is cut or perforated to form a fibre-reinforced sheet. These sheet materials are usually products composed of fibres, fillers and binders. The quality and composition of these three components and the production process determine the performance of the gasket. Nitrile rubber (NBR) is the most commonly used high-quality adhesive for gasket materials. Due to its excellent technical properties, aramid is the most basic fibre used in these types of non-asbestos gaskets.

Commonly used fibres in fibre-reinforced boards

ARAMIDE FIBER

Aramid fibre is a kind of aramid fibre with high strength, high stability and medium temperature adaptability. Fibrils can fibrillate.

Carbon Fibre

Carbon fibre contains thermal conductivity, ensures rapid heat dissipation, and allows high-temperature performance (except for oxidizing atmosphere). These fibres have a wide range of chemical resistance and can be used in the pH range of 0-14, but cannot be used in an oxidizing environment.

Cellulose Fibre

Fibres made of cellulose are suitable for applications requiring low temperature and medium pressure. Raw Fibrils can fibrillate.

Glass Fiber

Glass fibre is an inorganic metal silicate composite with good strength and moderate chemical resistance. These fibres are suitable for medium and high-temperature applications. Fibrillation does not occur in the fibres.

Mineral fibre

Mineral fibre, also known as “mineral wool”, is an inorganic fibre composed of metal silicate with a wide range of diameters. This fiber is suitable for medium and high-temperature applications. The fibres form fibrils.

Advantages and disadvantages of fibre-reinforced gaskets

The advantages of fibre reinforced gaskets include:

- Affordable price and excellent availability

- Easy to cut/punch size

The disadvantages of fibre-reinforced gaskets include:

- The temperature resistance of the rubber adhesive is limited

2) Graphite Gasket

When using graphite gaskets, only graphite with a purity of >99% elemental carbon can be used. Not only the purity, but the composition of the ashes is critical to the performance of graphite gaskets. These washers are usually reinforced with stainless steel gaskets. The design of the rebar is the key. At present, expanded metal inserts of smooth metal and trimmed metal are more common.

The expanded metal optimizes the surface pressure distribution. The special graphite compression group allows excellent micro-sealing and adaptability. When replacing fibre-reinforced gaskets with graphite gaskets, the thickness of the gasket can be reduced. Graphite has excellent chemical resistance to various media. It can be used at an application temperature of 450°-550°C. Using expanded metal graphite gaskets, even metal gaskets can be replaced in many applications.

The advantages and disadvantages of graphite gaskets

The advantages of graphite gaskets include:

- Easily track any flange irregularity, Ra <12,5

- did not climb

The disadvantages of graphite gaskets include:

- Not resistant to the oxidizing environment

3) PTFE gasket

PTFE gaskets provide great chemical resistance. These gaskets will only be corroded by molten alkali metals and fluorine gas. In addition to their anti-stick properties, they also have excellent dielectric properties. Generally, the leakage rate of PTFE gaskets is very low. The only disadvantages of PTFE gaskets are a creep and poor mechanical properties.

The advantages and disadvantages of PTFE gaskets

The advantages of PTFE gaskets include:

- Dense sealing material

- Fully adapt to flange

- Has extremely strong chemical resistance

The disadvantages of PTFE gaskets include:

- Limited temperature resistance

- climb

4) Rubber gasket

The rubber gasket is formed by cutting or punching an industrial rubber sheet made of industrially produced rubber. The following rubber compounds can be made into flakes:

Nitrile rubber

Acrylonitrile-butadiene rubber can improve the chemical resistance and temperature resistance of neoprene. In addition, it has good hydrocarbon and oil resistance. This type of rubber is not suitable for chlorinated hydrocarbons, esters, ketones and strong oxidants. Temperature range: -30℃~ 100℃.

Silicone

Silicone contains excellent temperature characteristics and is not affected by ozone and sunlight. Hydrocarbons and steam cannot be used with this material. Temperature range: -60℃~200℃.

Chloroprene rubber

Neoprene rubber has excellent oil resistance, ozone resistance and weather resistance. Suitable for mild acids, alkalis, salt solutions, petroleum, solvents, oils and fuels. Not recommended for strong acids or hydrocarbons. Temperature range: -45℃~100℃.

Natural Rubber

The natural rubber has excellent recycling properties. Inorganic salts, mild acids and alkalis are also not a problem for it. Oils and solvents, or where exposed to ozone, oxygen or sunlight are prominent natural rubber is not recommended. Natural rubber is composed of elastomers and has great resistance to ozone, oxygen or sunlight. Temperature range: -60℃~ 80℃.

Ethylene Propylene Rubber

Ethylene-propylene rubber is composed of elastomers and has great resistance to ozone, strong acids and alkalis. Not suitable for solvents and aromatic hydrocarbons. Temperature range: -50℃~150℃.

Butyl rubber

Butyl rubber is composed of elastomer, which provides great resistance to ozone and gas penetration. It is suitable for weak acids, weak bases and weak acid esters, but has little resistance to oils and fuels. Temperature range: -40℃~150℃.

Styrene-butadiene rubber

SBR is suitable for weak organic acids and medium-concentration chemicals. However, it is not suitable for strong acids, most hydrocarbons or ozone. Temperature range: -50℃~100℃.

Fluoroelastomer

Fluoroelastomers are excellent oils and greases, fuels and aliphatic and aromatic hydrocarbons. Some flame retardant hydraulic fluids and synthetic aircraft engine oils are also suitable. Temperature range: -20℃~200℃.