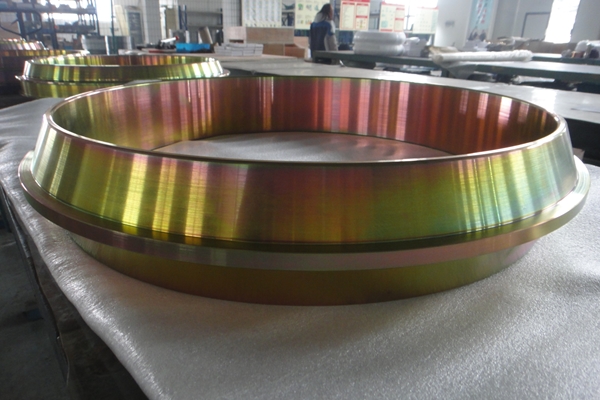

Custom Ring Joint Gasket

Ring Joint Gaskets are machined from a variety of types of forged solid metals such as Soft iron, Stainless Steel, Low carbon, and alloy metals such as Inconel Duplex, Monel, Hastelloy, Titanium, etc.

They are designed for high-pressure and temperature applications by selecting the suitable shape and material. The hardness of the RTJ gasket body should always be 20-30HB less than the hardness of the flanges to prevent flange deformation.

Oval Style R-type oval ring joint gasket

Ring joint gasket with oval cross-section is initially developed for high temperature and pressure applications. It is still used in the old type of round bottom groove today.

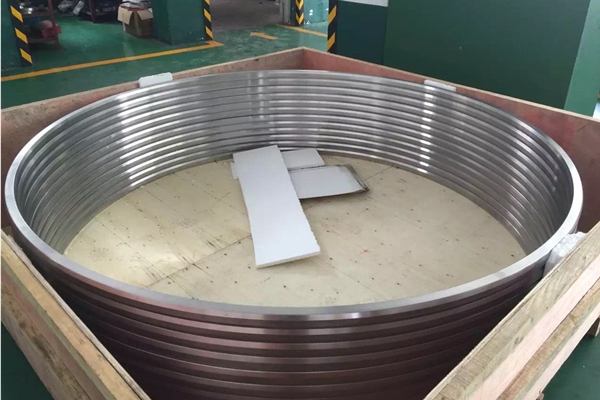

Oct Style R type Octagonal ring joint gasket

Ring joint gasket with Octagonal cross-section is preferred by modern grooved flanges and has a higher sealing efficiency than oval types

RX Style RX Ring Joint Gasket

RX is used at pressures up to 15,000 psi (103 MPa). RX type Ring Joint Gasket is made to API 6A and interchangeable with standard Octagonal rings, it can take advantage of container fluid pressure well to effect a seal.

BX Style BX Ring Joint Gakset

All BX Ring Joint Gaskets incorporate a pressure balance hole to ensure equalization of pressure which may be trapped in the grooves, it is only used in API 6BX flanges. BX is used at pressures up to 15,000 psi.

More styles such as IX, HX, AX, and LENS Ring Joint Gaskets are produced by your demand, when you need non-standard Ring Type Joints, please kindly provide your drawings.

The Ring Joint Gasket was initially developed for high pressure and temperature applications found in the petroleum industry and is primarily used in the oil field on drilling and completion equipment.

Furthermore, Ring Type Joint product range can also be found on valves and pipework assemblies, along with some high integrity pressure vessel joints.

| Material | Identification | Max Hardness |

| Soft Iron | D | 90 |

| Low Carbon Steel | S | 120 |

| 5Cr0.5Mo | A182-F5 | 130 |

| SS304 | SS304 | 160 |

| SS316 | SS316 | 160 |

| SS316L | SS316L | 150 |

| SS321 | SS321 | 83 |

| SS347 | SS347 | 83 |

| SS410 | SS4109 | 86 |

| Alloy 625 | INC 625 | 89 |

| Alloy 825 | INC825 | 92 |

Ring Joint Gasket Manufacturers FAQ

1. What are ring joint gaskets?

Ring joint gaskets are metal seals for high-pressure and high-temperature applications. They come in two cross-sections: octagonal and oval.

Ring joint gaskets are used to connect RTJ flanges to create a strong seal between two mating flanges. When the flange is bolted, the ring joint gasket is squeezed into the groove of the flange to form a tight seal between the mating flanges. To avoid damaging the flange, the ring joint gasket material must be softer than the flange material.

2. What are the basic types of ring joint gaskets?

Ring joint gaskets are manufactured according to the application: Style R(including R octagonal gasket and R oval ring gasket), Style RX and Style BX are common standard types. Non-standard Ring Joint Gaskets were often required in special applications, such as IX ring gaskets, HX seal Rings, AX ring gaskets, and Lens Ring Joint Gasket or customized by drawing.

1) Style R gaskets

Style R gaskets are divided into R octagonal gaskets and R oval ring gaskets according to the different cross-sections. 5,000 PSI is the maximum pressure that can be applied to a Style R gasket. The ring gasket is regarded as a semi-pressure energized ring gasket. API 6A and ASME B16.20 flanges are available as well as API 6B and ASME/ANSI B16.5 flanges. All relevant standards are followed in the manufacturing of Style R Ring Joint gaskets for the following flange designations:

BS 1560 > API 6A > ASME / ANSI B16.5 > MSS SP44 ( ASME 16.47 SERIES A)

R octagonal gasket

R octagonal gasket is designed with an octagonal-shaped section. There is a slight difference between the average diameter of the gasket groove and the average diameter of the R octagonal gasket. The angle between the ring gasket and the bevel face of the gasket groove is around 23°. Only modern flat bottom groove flanges fit the octagonal shape.

R oval ring gasket

R oval ring gasket is manufactured in oval-shaped sections. Round and flat bottom rings groove flanges fit the oval ring. R octagonal gasket and R oval ring gasket in a similar function: they seal by an initial line contact or an edging action as the compressive forces are applied. However, the R oval ring gasket has a lower sealing efficiency than the etageres.

2) Style RX gaskets

API 6A and ASME B16.20 gaskets are compatible with API 6B and ASME/ANSI B16.5 flanges. Style RX Gasket, as one special kind of octagonal gasket, is developed and improved on the basis of style R gasket. It has good sealing as the contact between the gasket and the ring joint faces, especially the outside face, and is pressed tightly to keep good sealing performance. Gaskets in style RX are designed for pressures up to 5,000 pounds per square inch. RX Ring Joint Gasket is one kind of pressure-energized ring gasket.

3) Style BX

Style BX, as one special kind of octagonal gasket, is manufactured in accordance with API 6A and is suitable for use in high-pressure API 6BX flanges. Pressures up to 20,000 psi can be handled by Style BX. To equalize pressure across sealing faces, all BX sizes have a pressure relief hole. BX ring-type joint gasket is one kind of pressure energized ring gasket.

Type SRX and SBX gaskets are the same design as the Type RX and BX gaskets. They are manufactured to API 17D and are suitable for subsea wellhead and Christmas tree equipment. The “S” indicates that these gaskets have cross-drilled holes to ensure that any liquid trapped on either side of the ring gasket will flow to the I.D. hole. SRX ring gaskets are typically used for underwater 6BX and/or 17D RTJ flanges.

3. What are the standards of ring joint gaskets?

Ring joint gaskets are manufactured according to any standard and non-standard sizes, including the standards of API 6A, API 17D, ASME B16.20, DIN 2693-67, JPI-7S-23-72, and other standards to suit API 6A Type 6B and 6BX flanges meet ASME B16.5, ASME B16.47 Series A & B.

4. What are the applications of ring joint gaskets?

There are many applications of ring joint gaskets which include:

- Oil and gas industry

- Petrochemical industry

- Power plant technology

- Flange connections

- Pipe connections

- Heat exchangers, valves, pumps, compressors, boilers, and other types of industrial equipment

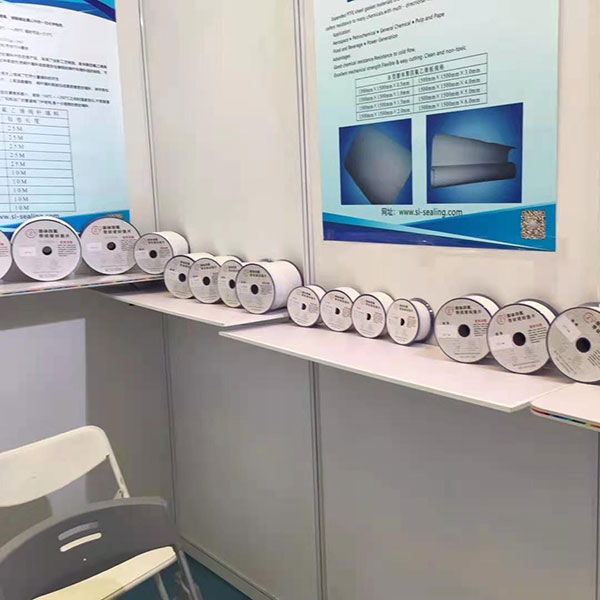

5. What is the technical literature on ring joint gasket?

1) Surface Finish

Style R and RX gaskets shall have a surface finish not rougher than 1.6μm (63μin.) roughness. Surface finish of Style BX gaskets shall not exceed 0.8 mm (32 inches).

2) Material

Ring Joint Gaskets generally are made from processing metal materials including soft iron, low carbon steel, alloy steels (such as Alloy600, Alloy625, Inconel825, Incoloy200, Hastelloy, Super Delex, Titanium, Monel400, etc), stainless steels (such as ss304, SS316L, SS321, SS347, SS410 and so on), etc. All the materials are selected with High-quality standards according to ASTM.

6. What are the characteristics of Ring Joint Gasket Flanges?

Ring connection flanges are fundamentally different from other types of flanges used in the piping and plumbing industry. The main features of RTJ flanges are:

- RTJ flanges use steel rings instead of flat composite gaskets. The spacer is installed on the machined groove.

- Sealing is achieved by the deformation of the soft metal gasket, which flows into the fine structure of the hard flange material.

- RTJ flanges provide first-class metal-to-metal sealing.

- Raised surfaces may be present in ring connection flanges, but it does not contain pressure. However, when tightening RTJ flanges, if the raised surfaces touch each other, the additional load is transferred to the faces, which in turn, provides connection integrity during over-tightening, vibration, and movement.

- Assembling and disassembling them is very easy.

7. What are the specifications of ring joint gasket flanges?

The edge (periphery) of each ring joint flange is usually marked with the letter R and the corresponding ring groove number. RTJ flanges are specified by the following parameters:

- Flange Size (Connecting Pipe Size)

- Flange material and grade

- Design Standard

- Pressure Class Rating (Temperature and Pressure rating)

- Flange face type

- Coating or Surface treatment requirements

- Dimensional requirements

- Application service type

8. What are the dimensions of ring joint gasket flanges?

The dimensions of RTJ flanges are usually specified in the design standard. For example, when the design code is ASME B16.5, for flanges under 24 inches, RTJ flange size tables are provided for each pressure rating class. For RTJ flanges over 24 inches, RTJ flange dimensions are provided in ASME B16.47.

So basically, for standard flanges, RTJ flange size is fixed and does not vary by manufacturer. However, custom RTJ flanges can also be manufactured, the buyer needs to specify the flange size.

9. What are the advantages and disadvantages of ring joint gasket flanges?

RTJ flanges are one of the most effective flanges for high-temperature pressure lines in process piping systems. The ring and groove design utilizes internal pressure to increase the sealing capability of the connecting flange. As the working pressure increases, the sealing performance improves. RTJ flanges are also suitable for cyclic stress and corrosive fluids.

The main disadvantage of the annular connecting flange is its high cost due to its complex structure and precise machining control of the metal annular gasket and annular connecting groove. In addition, when disassembling the ring joint flange connection, it is necessary to force the flange apart to release the ring from the groove. This may require sufficient space, which limits the use of RTJ flanges in crowded installations.

10. What are the differences between ring joint and raised surface?

1) Raised surface

This is the most common type found in processing plants. It is instantly recognizable when you see it. In this model, the surfaces of the connecting pads are raised. The bolt ring is always below the gasket surface.

The advantage is:

- You can use a wider range of gaskets – from spiral wounds to flat ring types.

- It is more accessible due to the raised surface. Therefore, it is much easier to replace worn washers.

- This design concentrates more pressure on a smaller gasket area. This in turn helps the joints better handle stress control.

- It is also useful when you need to better separate the two flanges of the connection.

2) Ring Joint

These are more commonly used in applications where high pressure or high temperature is an issue. These are class 600 or higher flanges or where temperatures typically exceed 427 degrees Celsius.

These flanges can be identified because they have grooves cut into their service. Metal gaskets fit into these grooves and then compress to create a strong seal. The liner was somewhat broken during processing but fit perfectly in the space.

The advantage is:

- Metal-to-metal sealing is possible. These materials are much stronger and can withstand corrosion caused by high temperatures, high pressures, and chemicals.

- Grooves allow for a tighter fit and can be useful where space is an issue.

- Depending on the type of gasket used, the surfaces may be in direct contact with each other.

- Once the gasket is tightened, it will no longer compress. As a result, it is more resistant to vibrations and movement.

- Your options are reduced when it comes to the types of gaskets you can use. However, if you choose the right type of job, the seal is highly reliable and robust.

As you can see, both types of flanges have advantages. You need to use the best design options for your project. It is good to remember that you should always use the correct connection for the best connection possible. Using RF connections on RTJs is disastrous. It might work at first, but with this kind of tinkering, it’s bound to go wrong later.