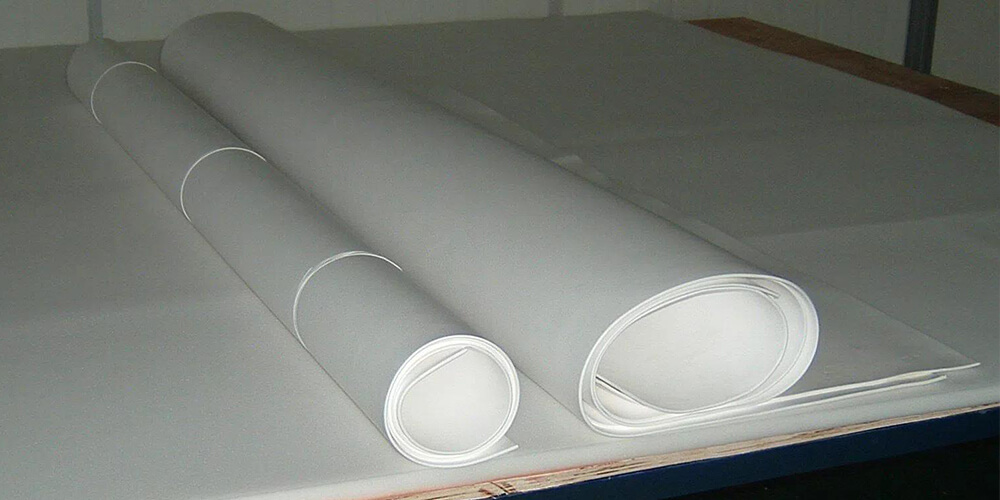

Expanded PTFE Sheet

Expanded PTFE Sheets are made from 100% virgin PTFE resins. Expanded PTFE sheet using a special process that produces a uniform and highly fibrillated microstructure with a great lot of fibres running in multi-direction. It is food approved product and has excellent resistance to a wide range of chemicals, making it a popular sealing material in the food, drink, and pharmaceutical industries. It has excellent sealability, cuts easily, and separates cleanly from flanges after use.

Expanded PTFE Gasket

Expanded PTFE Gasket is cut from Expanded PTFE gasket sheet, our expanded PTFE gasket sheet made with only pure PTFE resins. It is suitable for use in steel flanges as well as flanges where a highly compressible gasket is required. Expanded PTFE Gasket is also suitable for sealing flanges with irregular surfaces. It will not exhibit the cold flow problems associated with virgin PTFE or the hardness problems of some other filled PTFE products. It has excellent sealability, cuts easily, and separates cleanly from flanges after use

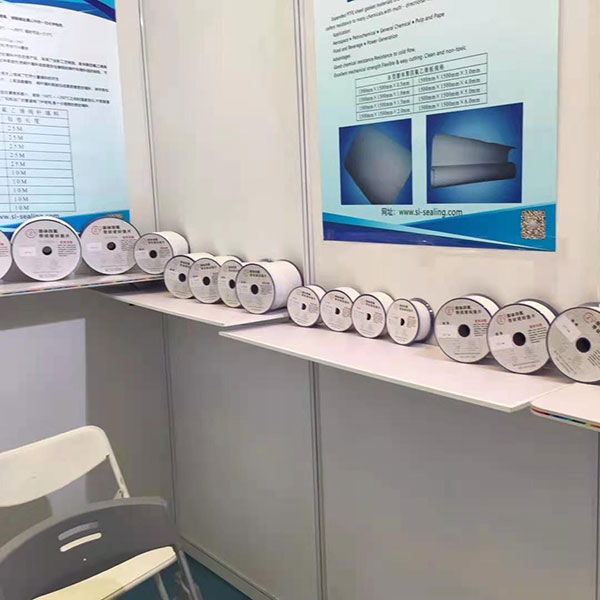

Expanded PTFE Joint Sealant

Expanded PTFE joint sealant tape is a new soft tape gasket product made of 100% PTFE. which is developed by using a highly specific treatment on the PTFE Fluorocarbon material. It is a form-in-place gasket, so it nearly can be used on any sealing surface. Especially for the irregularities and damaged flange surface. It is supplied with a self-adhesive backing for easy fitting.

Expanded PTFE Valve Stem Packing

Expanded PTFE Valve Stem Packing is engineered through an expansion process, which provides absolute reliability, chemical resistance, and the lowest total cost of ownership. It eliminates stem wear, resists chemical attack, and performs reliably across extreme temperatures

Expanded PTFE Manufacturers FAQ

Expanded PTFE FAQ Guide

Expanded PTFE is one of the main products in Bandak Sealing, here we summarize this FAQ guide to help our clients to know more about expanded PTFE. If you have any questions about purchasing Expanded PTFE from China, please feel free to send an inquiry to us.

1. What is Expanded PTFE?

Expanded PTFE is a new type of medical polymer material made of PTFE resin through special processing methods such as stretching. White, elastic, and flexible, the network structure is formed by the connection of these microfibers, these microfibers form countless pores so that the Expanded PTFE can be bent arbitrarily, good blood compatibility, biological anti-aging, used to make artificial blood vessels, cardiac patches, and other medical products.

Therefore, the use of this material for soft tissue filling operations including rhinoplasty has the advantages of natural appearance, no displacement, degeneration, and fewer complications. Since there is only a limited amount of cellular tissue that can grow into the pore, it’s not a big deal if you have to pull it out because it’s a long chain of carbon atoms wrapped in fluorine.

Expanded PTFE is a man-made material with extremely stable physical and chemical properties due to its special molecular structure. No rejection reaction was seen after implantation of artificial blood vessels, artificial dura mater, cardiac patch, es, etc., which fully proved that the material has good biocompatibility.

Expanded PTFE expands the dispersed PTFE resin into a porous, low-density, high-toughness material through certain processing technology. Because Expanded PTFE has excellent comprehensive properties of PTFE materials, as well as a large temperature range, high mechanical strength, and some new characteristics such as porosity, air permeability, hydrophobicity, and excellent flexibility during use, has been widely used in medical, environmental protection, textile and clothing, petroleum, chemical, new energy, and other fields.

In addition, Expanded PTFE and specific substrate composite polymer composites have excellent properties, and can also be successfully used in energy saving and emission reduction, PM2.5 particle filtration, water purification, artificial organs, etc. more and more attention and attention.

2. How is Expanded PTFE made?

Here we summarize the manufacturing processes for expanded PTFT:

1) Selection of Raw Materials

Due to the linear and completely symmetrical structure of the PTFE molecule, the PTFE molecule has less star-neutral intermolecular force, low surface tension, and low mechanical strength. To achieve mechanical strength for practical applications, sufficient molecular weight is required, typically 5×10*- 8×10*. The larger the molecular weight, the more severe the entanglement between molecules. It is not easy to get lost; the molecular chains in the amorphous region are more entangled, and the molecular chains are not easily pulled out.

Therefore, a PTFE resin suitable for stretching needs to have a high degree of crystallinity. The higher the crystallinity, the higher the strength. Therefore, the PTFE used for stretching should have higher crystallinity (preferably above 98%) and larger molecular weight.

PTFE resin is divided into suspension resin, dispersion emulsion, and dispersion resin. The dispersed resin molecules are electrically neutral, and the low molecular chains will be arranged along the long axis of the particles, and linear crystallization will occur under a small shear force, which has excellent fiber-forming properties.

Moreover, the molecular weight and crystallinity of PTFE person resin are generally higher than those of suspension resin, and the crystallinity can reach 96%~98%, while the crystallinity of dispersion resin after sintering and molding is relatively large, and it is sintered at a temperature slightly higher than the melting point. can be obtained. The strength of the dispersed resin is higher, and the bending fatigue life is 2300 times that of the suspended resin. Therefore, the raw material of Expanded PTFE is generally selected from dispersion resins.

2) Formation Process

At present, Expanded PTFE is generally prepared by a dispersion resin push molding process. The initial blank is pressed into extrudates of various shapes, then the extrudates are calendered into sheets, heated and dried to remove the extrusion aid, and then stretched in one direction, two directions, or multiple directions at a temperature of 35°C to 327°C, and finally Heating above the melting temperature for a set period of time and cooling to room temperature.

Each process of Expanded PTFE molding has a strong purpose and ultimately ensures that the material has a certain strength, high stretching ratio, and good pore-forming properties during the stretching process. The booster is used to control the friction between the resin particles and between the resin and the pushing equipment during the pushing process; the preform is squeezed to make the PTFE product fit more closely and eliminate the air in the resin and holes to make the paste firmer.

Higher extrusion and calendering can make the material more dense and oriented, producing a certain amount of oriented microfibers, and increasing the tensile strength of the material in preparation for the final stretching process. The final stretch orients the material and microvoids appear, increasing the material’s strength and creep resistance.

3. What are the properties of Expanded PTFE?

Electrical conductivity, thermal conductivity, catalytic and chemical activity, adsorption and magnetic activity, odor absorption, radial, impedance, reflection, selective permeability, transparency,/opacity, dimensional stability, high dielectric constant, low dielectric Constants, various hardness and stiffness, high/low wear resistance and osmotic protection and controlled fluid flow

4. What are the advantages of Expanded PTFE compared with Ordinary PTFE?

A major advantage of Expanded PTFE over regular PTFE is that it is highly compressible. This is because it has a multidirectional fiber structure that allows it to perform well under different surface pressures. The material also has good adaptability to the sealing surface.

Another advantage of Expanded PTFE (also known as PTFE) is that it is customizable. This means that it can be modified for different applications to meet different physical properties such as hardness, surface energy, stiffness, etc.

Expanded PTFE also works well in extreme environments, with performance levels far higher than the latter.

5. Why should you choose Expanded PTFE instead of PTFE?

Both PTFE and Expanded PTFE have excellent properties for industrial applications. But Expanded PTFE has a wider application range than PTFE. The multidirectional fiber structure of Expanded PTFE enables it to perform under high surface pressure conditions. For maximum safety requirements, such as flange sealing for oxygen delivery pipes. Expanded PTFE is a suitable material because it can be highly customized. Expanded PTFE has a better performance rate temperature than PTFE. It is so in demand in the market that it is now manufactured in different heights, densities, and sizes.

6. Expanded PTFE vs. PP: Value in terms of durability?

Expanded PTFE has some potential advantages over PTFE, so PTFE should be strictly recommended in special cases. Polypropylene mesh causes a strong scarring reaction, while Expanded PTFE can be manufactured according to the purpose of use. So today’s Expanded Teflon is a very good document to be placed in direct contact with the internal organs. Although Expanded PTFE is very expensive, it should be used for laparoscopic ventral hernia repair, as well as for open repairs when the mesh is placed in the abdominal cavity.

So far, no mesh-related complications have been reported when using Expanded PTFE, while some of the typical problems of PP such as migration, infection, and fistula formation are not well-reported.

7. What is the function of Expanded PTFE?

The full name of the Expanded material commonly known in the field of plastic surgery is Expanded PTFE surgical soft tissue patch, another name: Expanded PTFE (ePTFE) surgical patch. Its chemical structure is a long chain of carbon atoms wrapped by fluorine atoms. Expanded PTFE is a man-made material with extremely stable physical and chemical properties due to its special molecular structure. There are no reports of clinical rejection after implantation in various parts such as artificial blood vessels, artificial dura mater, and cardiac patches, which fully proves that the material has good biocompatibility.

8. What is the application principle of Expanded PTFE?

Expanded PTFE resin is made of PTFE dispersion resin through special processing technology. Ultrastructure with “knot fibers”. By controlling the distance between the knots, it can induce the ingrowth of its own tissue cells. Therefore, the biggest difference between using Expanded PTFE as a filler material and previous materials is the way the tissue heals.

That is to say, Expanded PTFE is a tissue healing method with tissue ingrowth, while traditional silicone rubber is a fiber-wrapped tissue healing method. Therefore, the use of this material for soft tissue filling operations including rhinoplasty has the advantages of a realistic and natural appearance, no displacement and degeneration of the prosthesis, and fewer complications. At the same time, since the number of cells and tissues growing in the micropores is very limited, it is not difficult to remove these substances.

9. Where can Expanded PTFE be used?

1) High-Performance Fabric

Expanded PTFE is lightweight, durable, waterproof, and windproof, and can be processed into a variety of fabrics with varying levels of water permeability or “breathability.” The result: a unique high-performance fabric that is both comfortable and protective.

2) Medical Implants

Because Expanded PTFE (ePTFE) is pure inert, medical products made by it are highly biocompatible and do not cause rejection by the body. Expanded PTFE (ePTFE) has a microporous structure and can be used in a variety of rehabilitation solutions, including artificial blood vessels and patches for soft tissue regeneration, and procedures for vascular, cardiac, general, and orthopedic surgical sutures, allowing physicians and patients to benefit. Our medical products work in harmony with the body’s own tissues to restore their normal function.

3) Fluoropolymer fibers

Expanded PTFE (ePTFE) fibers are characterized by high strength, low shrinkage, abrasion resistance, and UV resistance, ensuring good stability and integrity in extreme environments.

This fiber is versatile and can be woven, braided, braided, or sewn into a wide variety of fabrics, including compression bags, sewing thread, construction fabric, and dental floss, to name a few.

4) Gaskets and Tape Sealants

Industrial expansion PTFE gasket (6 pieces)

Expanded PTFE (ePTFE) has good chemical resistance, anti-wear properties, and strong high-temperature and low-temperature resistance, which is very suitable for the transportation and sealing of industrial liquids.

LongSeal gaskets and sealing products, including flat, square tape, and in-situ sealants, can be used on flanges of any size or specification.

5) Industrial thin film technology

Expanded PTFE (ePTFE) membranes can be processed into a variety of unique microstructures to produce a range of high-performance filter media with pores that block a variety of particles and allow air to pass. Expanded PTFE (ePTFE)’s unique chemical inertness and thermal stability make it suitable for filtration conditions such as harsh chemicals and high temperatures.

Expanded PTFE-made filter bags, cartridges, microfiltration membranes, pores, and adsorption products address a wide variety of pollution control and disposal challenges in industrial applications including chemical plants, incinerators, food and pharmaceutical manufacturing, foundries, and more.

6) Advanced dielectric materials for electronic devices

The inherent low loss and dielectric constant of Expanded PTFE (ePTFE) make it an ideal insulation material for wires and cables: its unique porous structure minimizes loss and distortion, enables signal transmission near the speed of light, and is thermally stable sex and mechanical flexibility. At the same time, Expanded PTFE (ePTFE) can also reduce the size and weight of the overall interconnection, and is a good filling medium material.

Expanded PTFE-made electronic products include copper and fiber optic cables, cable systems, printed circuit board materials, conductive interface products, and shielding gaskets for use in telecommunications, computer, test and measurement, defense, aerospace markets, and many other high-performance and challenging fields.

10. What are the product forms of Expanded PTFE?

Tape type: electronic wire and cable

Membrane/Membrane: Expanded PTFE Membrane, Filtration Membrane, Stent Grafting, Breathable Membrane, Fuel Cell Membrane Electrode System, Dielectric Material, Battery/Capacitor Separator

Plate type: EMI gasket, sealing gasket, medical patch

Fibers: Braid/Sewing Thread, Dental Floss, Filler, Filter Felt

Tube Type: Peristaltic Pump Tube, Vascular Graft, Environmental Screening Module

11. Conclusion

On the basis of maintaining the advantages of traditional PTFE, Expanded PTFE greatly improves some deficiencies of PTFE by modifying the structure of PTFE, so that its comprehensive performance is improved, and its application range is continuous. expand.

However, due to the long-term monopoly of technology, the development and promotion of Expanded PTFE are not smooth, and there are still many works worth studying, including the relationship between the structure and properties of Expanded PTFE, and the creep characteristics of Expanded PTFE. These works have practical guiding significance for the industrial production and popularization of Expanded PTFE.