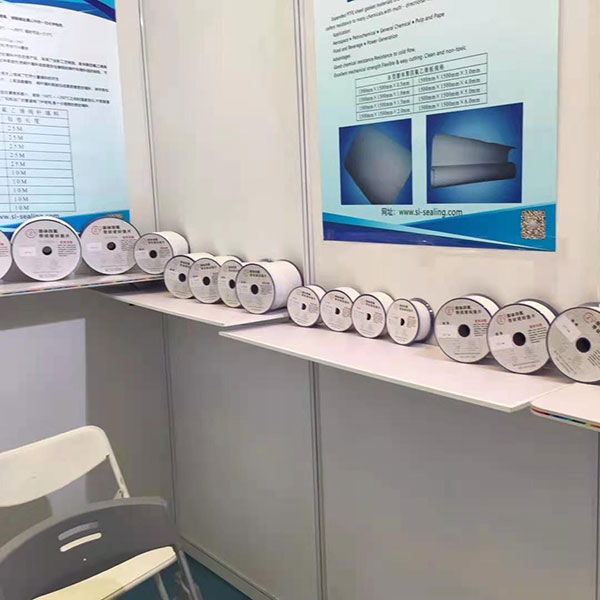

Custom Expanded PTFE Sheet From China

Expanded PTFE Sheets are made from 100% virgin PTFE resins. Expanded PTFE sheet using a special process that produces a uniform and highly fibrillated microstructure with a great lot of fibers running in multi-direction.

It is food approved product and has excellent resistance to a wide range of chemicals, making it a popular sealing material in the food, drink, and pharmaceutical industries. It has excellent sealability, cuts easily, and separates cleanly from flanges after use.

| Test Properties | Standard Parameter | Test Result |

| Material | 100% Virgin PTFE | |

| Color | White | |

| Tensile strength(MPa) | ≧7Mpa | 17Mpa |

| Density(g/cm) | 0.75g/cm3 | |

| Max Working Temperature | Safe Temperature | 200℃ |

| Sealing Leakage | ≦1.0×10ˉ3 | 0.75×10ˉ3 |

| Compression Rate | ≦60% | 48% |

| Compression deformation rate | ≦40% | 38% |

| Resilient Rate | ≧6% | 12% |

| Volatility | ≦0.5% | Refer to FDA21CFR177.1210 |

| PH value | 0-14 | |

| Test Size: | 1500x1500x3mm |

TEST CONDITION REMARK:

1, Test Temperature: 20℃

2, Test Medium:99% Nitrogen

3, Test Medium Pressure:4.0Mpa

4, Compression rate and Resilient Test According to JB/T10688-2006 Regulation, Test Load is 17.25Mpa

5, Sealing Leakage Test According to JB/T10688-2006 Regulation, Preload Pressure is 17.25Mpa.

Distilleries, petrochemical, food and beverage, pharmaceutical, general chemical, power generation, iron and steel manufacturing, pulp and paper, etc.

Seal nearly all aggressive chemicals 0-14 PH

- Excellent tension; complete resistance;

- Suitable for filling wide flange gaps;

- Easy to install;

- Easy to cut, punch and draw;

- Withstand high loads; extremely low tendency to cold flow;

- Excellent recovery properties; suitable for changing loads;

- Suitable for high temperature applications;

- Allows precise mathematical methods to seal applications;

- Harmless in contact with food;

| Item | Size(mm) | Thickness(mm) | Size(inch) | Thickness(inch) |

| 1 | 1500mmx1500,3000mm | 0.5 | 60” x 60” | 1/64” |

| 2 | 1500mmx1500,3000mm | 1 | 60” x 60” | 1/32” |

| 3 | 1500mmx1500,3000mm | 1.5 | 60” x 60” | 1/16” |

| 4 | 1500mmx1500,3000mm | 2 | 60” x 60” | 5/64” |

| 5 | 1500mmx1500,3000mm | 3 | 60” x 60” | 1/8” |

| 6 | 1500mmx1500,3000mm | 4 | 60” x 60” | 5/32” |

| 7 | 1500mmx1500,3000mm | 5 | 60” x 60” | 3/16” |

| 8 | 1500mmx1500,3000mm | 6 | 60” x 60” | 1/4” |

more sizes can be customized

Expanded PTFE Sheet Manufacturers FAQ

What Is Expanded PTFE Sheet?

Expanded PTFE sheet, also named ePTFE sheet, is a highly versatile sealing material made from 100% virgin PTFE through a specialized expansion process. The expansion creates a microporous structure, significantly improving flexibility, compressibility, and sealing capabilities. Widely recognized for its excellent resistance to extreme temperatures, aggressive chemicals, and mechanical stress, ePTFE sheet is the preferred choice across various industrial applications.

Key Properties

1. Chemical Resistance

ePTFE sheet offers excellent resistance to virtually all chemicals, including acids, bases, solvents, and hydrocarbons, making it ideal for use in chemical processing, pharmaceuticals, food and beverage, and more.

2. Wide Temperature Range

ePTFE sheets operate effectively in temperatures ranging from -240°C to +260°C (with peak intermittent temperatures of up to +315°C), ensuring reliable sealing across a wide temperature range, from cryogenic to high-temperature service.

3. Superior Compressibility and Conformability

The expanded structure enables the sheet to easily conform to rough, irregular, or damaged surfaces, making it ideal for applications where a secure seal is essential, even under low bolt loads.

4. Low Creep and Cold Flow

Expanded PTFE sheets have an outstanding creep relaxation rate, maintaining their sealing properties under sustained pressure. This significantly reduces the likelihood of leaks and prolongs the service life of the sealing component.

5. Non-Stick, Low Friction Surface

Their inherent non-stick and low-friction properties ensure minimal material adhesion, facilitating easy maintenance and contamination-free operation, particularly critical in food, pharmaceutical, and cleanroom environments

6. FDA and Food-Grade Compliance

Expanded PTFE sheets are FDA approved. They are suitable for hygienic sealing applications within the food, beverage, and pharmaceutical industries

7. Electrical Insulation and Dielectric Properties

The excellent dielectric strength of ePTFE sheets makes them ideal for electrical insulation applications, protecting equipment under high voltages and temperatures.

Specifications of Expanded PTFE Sheet

Temperature Range:

Continuous: -240°C to +260°C

Peak: up to +315°C

Pressure Range:

Vacuum up to 3,000 psi (200 bar)

Chemical Compatibility:

Full pH range (0-14), resistant to aggressive chemicals, acids, alkalis, and hydrocarbons.

Thickness Options:

Common: 1.5mm, 3mm, 6mm (custom thickness available)

Applications of Expanded PTFE Sheets:

Chemical & Petrochemical Industries:

Gaskets and seals for aggressive chemicals and corrosive substances; Sealing solutions in reactors, pipelines, valves, and pumps.

Food, Beverage & Pharmaceutical Industries:

FDA-approved sealing for hygienic processing equipment; Gaskets for sterilizers, mixers, and filling machines.

Oil & Gas Industry:

Reliable sealing of pipelines, storage tanks, and heat exchangers; Suitable for harsh conditions involving hydrocarbons and extreme pressures.

Power Generation:

Steam turbine and boiler sealing solutions; High-temperature sealing applications in power plants.

Aerospace & Automotive:

Seals and gaskets that withstand high temperatures, chemicals, and mechanical stress; Vibration-damping components.

Medical & Electronics:

Biocompatible seals for medical devices and pharmaceutical equipment; Electrical insulation and dielectric shielding for electronic components.

Why Choose Us for Expanded PTFE Sheets?

Our sheets are made from virgin PTFE, comply with industry standards, and are tested for consistent, reliable performance. We offer:

Bulk Supply & Competitive Pricing, Custom Manufacturing wide range of thicknesses, sizes, and private-label/branding options

Fast Lead Times: Efficient supply chain and flexible MOQ; Quality Assurance: Strict quality control standards

Selection & Installation Tips

Chemical Compatibility: Always confirm the media to be sealed and select an ePTFE sheet with full chemical compatibility.

Operating Conditions: Choose the sheet thickness and density based on flange surface condition, temperature, and pressure requirements.

Torque Management: Avoid over-compression during installation; use calibrated torque for best sealing and longevity.

Custom Sizing: For irregular or damaged flanges, ePTFE’s adaptability can compensate for uneven surfaces.

Frequently Asked Questions

What makes ePTFE sheets superior to pure PTFE sheets?

The expanded structure delivers higher compressibility, better adaptability to rough surfaces, lower bolt load requirements, and improved sealing performance under cycling loads and low stress.

Are ePTFE sheets safe for food and pharmaceutical use?

Yes. Our ePTFE sheets are FDA approved, ensuring compliance with strict hygiene and safety standards.

How do I select the right thickness?

Select thickness based on flange irregularities, surface condition, and pressure class. Thicker sheets conform better to rough surfaces, but ensure that the sealing gap does not exceed gasket design recommendations.

What is the typical service life?

Expanded PTFE sheets can last 30+ years in standard applications, with minimal loss of sealing capability.

Conclusion

Expanded PTFE sheet is a highly effective sealing solution for versatile industrial applications. With superior chemical compatibility, wide temperature tolerance, and excellent compressibility, these sheets offer high reliability and performance. For further inquiries or bulk orders, contact us today. We are committed to delivering superior expanded PTFE solutions as your requirements.