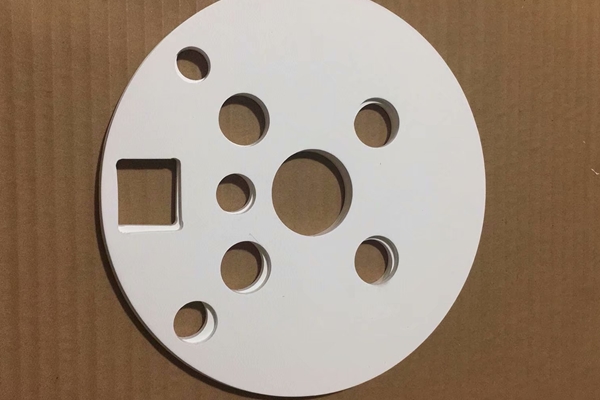

Custom Expanded PTFE Gasket

Expanded PTFE Gasket is cut from Expanded PTFE gasket sheet, our expanded PTFE gasket sheet made with only pure PTFE resins.

It is suitable for use in steel flanges as well as flanges where a highly compressible gasket is required. Expanded PTFE Gasket is also suitable for sealing flanges with irregular surfaces. It will not exhibit the cold flow problems associated with virgin PTFE or the hardness problems of some other filled PTFE products. It has excellent sealability, cuts easily, and separates cleanly from flanges after use

- Hand-holes and manholes

- All types of sealing flange

- Heat exchangers

- Compressors

- Pump, etc

| PROPERTY | STANDARD | VALUE |

| Color | – | White |

| Density | ASTM D792 | 0.75-0.95g/cm3 |

| Operating temperatures | – | -286 – 320°C |

| Compressibility | ASTM F36 | 45 % |

| Recovery | ASTM F36 | 12 -13% |

| Creep Relaxation | ASTM F38 | 35 – 36 % |

| Sealability (Nitrogen) | ASTM F 37B | 0.15 ml / hr |

| Sealability (Fuel A) | ASTM F 37B | 0.02 ml / hr |

| Service Pressure | – | Full Vaccum to 19 MPa |

| Tensile Strength Both directions | ASTM D638 | 19.6 MPa |

- Excellent sealing effect

- Gasket easy to cut

- Excellent chemical resistance and creep resistance

- Multi-directionally expanded PTFE has exceptional mechanical strength

- Cost savings

- High quality – long life – reduce changing gasket period – cut cost

- Easy and simple to install gaskets, a used gasket changed easily

- Customized sizes&shapes as required

- Sizes from 1/2” – 24” available, Customized size available

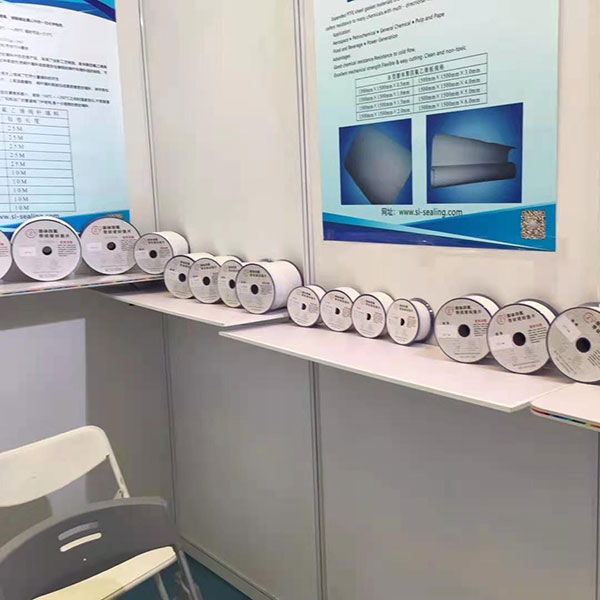

- Offers some of the largest sheet sizes in the industry

- Materials Standard

- High-quality raw material resin

- FDA 21 CFR 177.1550

Expanded PTFE Gasket Manufacturers FAQ

1. What is an expanded PTFE gasket?

Expanded PTFE gasket material is produced by expanding original PTFE material using a process that produces a uniform and highly fibrillated microstructure with equal tensile strength in all directions. The expanded PTFE gasket is softer and more flexible than regular PTFE gaskets, so it easily adapts to irregular and rough surfaces. The material is easier to compress and minimizes creep and cold flow.

Expanded PTFE has excellent dielectric properties and provides excellent thermal insulation over an operating temperature range of -200°C to 260°C. The expanded PTFE gasket is the most chemically resistant plastic known and is immune to most aggressive liquids, vapors, and gases

2. What are the features of the expanded PTFE gasket?

Expanded PTFE gaskets have many unique features:

1) No corrosion, no wetting, no pollution, no smell.

2) Can work efficiently from low temperature to +260°C.

3) Pure expanded PTFE gasket form has excellent electrical and thermal insulation.

4) Very soft material

3. What are the benefits of an expanded PTFE gasket?

The expanded PTFE gasket has similar properties to the regular PTFE gasket. The material is completely non-toxic and hygienic, with an operating temperature of up to 260°C. In addition, the expanded PTFE gasket offers the following benefits:

1) Chemical resistance with high linear strength

2) Low-pressure waterproof

3) Low dielectric constant

4) Excellent radial expansion and UV resistance

5) Different levels of porosity available – low, medium, and high density

4. What are the advantages of using expanded PTFE gaskets?

Experts recommend expanded PTFE gaskets because of their many benefits. This is because gaskets made of this special material have unique advantages for different applications. These are some of the reasons why an expanded PTFE gasket is a good material.

1) Excellent chemical resistance

Chemical resistance is an important quality that provides many applications. Its corrosion and chemical resistance makes it suitable for aggressive chemicals such as acids and bases. In fact, there are hardly any chemicals that can attack this material. This means that the material can be used in a range of applications involving chemical processing.

2) Temperature resistance

In industrial processing, it is crucial to use strong materials that can withstand high temperatures. This explains why an expanded PTFE gasket is widely used in the food industry, metallurgy, and chemical processing. In these industries, materials that are resistant to temperature changes are required.

3) Versatility

Today, there are different types of expanded PTFE gaskets to consider. Due to the use of different manufacturing techniques and compounds, you can find materials with different performance characteristics. This means you can get an expanded PTFE gasket that fits your performance requirements. In addition, you can find these gaskets in different thicknesses and compressed sheets. If you can’t get what you need, you can order custom ones from various manufacturers.

4) Non-corrosive properties

In the pharmaceutical or chemical industry, you should use materials with excellent corrosion resistance. That’s because you have to deal with harsh acids and chemicals. For example, since the expanded PTFE gasket does not wet, it is widely used for sealing and preventing leaks.

5) Thermal and electrical insulation

The benefit of an expanded PTFE gasket is that it does not get hot even when used in a process that generates heat. This means that it is used in different industrial processes that require thermal insulation. For example, if the process requires thermal insulation, this material can provide the required thermal insulation.

6) Availability

Today, you can get custom expanded PTFE gaskets for a range of industrial applications. All you have to do is provide the manufacturer with the exact specifications and your gasket will be made exactly to your needs.

5. What are the applications of an expanded PTFE gasket?

First and foremost, the conformal plastic found itself die-cut into rings and against the large flange face. Heavy duty bolts and nuts are tightened in a special way so that the compressive force applied by the installer surrounds the seal and lumen. The point is, that an expanded PTFE gasket can withstand the highest compression energies imaginable, and gaskets made from this flexible fluoroelastomer seal won’t rupture under pressure. Creep and blowouts are also impermeable, and the gasket can contain the high-pressure fluid flow. Because of these properties, expanded PTFE gaskets are expected to find use in applications that employ continuous thermal cycling. Seals can handle high and low-temperature transients in refineries and chemical processing plants, cryogenic facilities, and heat exchanger areas. Also tolerates thermal changes from low to high.

Pressure vessels store corrosive media. The substance is hot and kept under high pressure. Today, many gasket materials can withstand one or both of these energy threats. An expanded PTFE gasket can withstand all of these threats. The expanded PTFE gasket remains firm even when pressed down hard by both flange faces. Better yet, if the system using the gasket performs some kind of phase change, i.e. changing the processing temperature or storage pressure, then the gasket will not be affected. Fluoroelastomers are creep-free, robust, and reliable to withstand application and process transients.

1) Stabilize pumps and gearboxes

expanded PTFE gaskets are a popular choice for pump and gearbox retrofits due to their unique properties. They have shown the ability to prevent water from entering the bearing area, thereby reducing corrosion inside the housing.

2) Prevent sand particles from entering the gearbox from the outside

This is one of the most widely used expanded PTFE gasket applications, and its advantages are widely recognized by all types of gearboxes. The gasket allows quick removal of the instrument for various maintenance tasks and services. Expanded PTFE keeps grit and contamination out while facilitating routine inspections. Expanded PTFE gaskets help keep grit and debris out of your system when running your machine in harsh, dirty environments.

3) Increased Coupling Efficiency

In the chemical/petrochemical industry, expanded PTFE gaskets increase the efficiency of rotating equipment through a process known as “coupling pump/bank transfer”. It involves connecting the pumps of petrochemical plants to storage tanks for transportation. However, liquid and gas delivery systems do not have a common seal. Therefore, expanded PTFE gaskets are necessary for this application due to their superior performance or strength in providing the required watertight and airtight seals.

4) Prevents corrosive fluids from entering seals

Because expanded PTFE gaskets are impermeable to gases and vapors that can cause corrosion, they have been found to be excellent at preventing corrosive fluids from entering seals. Seals in any machine are an important part of keeping foreign objects out of the machine. However, with the constant use of harsh chemicals and alkaline solutions on these seals, it is not uncommon for them to deteriorate over time.

6. What are the differences between PTFE and expanded PTFE?

PTFE is a solid material that can withstand temperatures up to 260 degrees Celsius. The material has excellent corrosion resistance and long service life. This material is used in various industries such as food and petrochemical. The fact that it does not corrode anything that comes close to it makes it ideal for use in the food industry.

On the other hand, expanded PTFE is made from PTFE. This material is mainly used as a sealant. It is easily modified to meet different requirements such as stiffness and stiffness. The material can be stretched at high temperatures and has a smooth texture. Other interesting properties of this material include UV resistance, water resistance, and diffuse porosity. Therefore, this material is used in the biological and medical industries.

In fact, both expanded PTFE and PTFE have a wide range of industrial applications due to their properties. However, expanded PTFE has a wider range of applications than PTFE. Due to its fibrous structure, expanded PTFE can be used under high-pressure conditions. For safety purposes, materials can be tailored to provide better performance. Furthermore, it is highly desirable to produce it in different densities, sizes, and heights.

7. Why should you choose an expanded PTFE gasket instead of a PTFE gasket?

1) Introduction

PTFE stands for polytetrafluoroethylene. It is a synthetic fluoropolymer of tetrafluoroethylene. Expanded PTFE is made from 100% original PTFE and can be used as a sealant. It’s lightweight but sturdy. These materials are used in a variety of industrial applications, but you should know whether PTFE or expanded PTFE is more suitable for your application. To get an answer to this crucial question, you must understand the differences and uses between the two materials.

2) The difference between polytetrafluoroethylene and expanded polytetrafluoroethylene

PTFE:

- PTFE or Teflon is a solid material.

- It can work well in environments with temperatures up to 260 degrees Celsius.

- It is a durable material because it can withstand corrosion.

- It doesn’t cause much friction.

- Industries suitable for using PTFE are oxidizing media, mineral oils, pharmaceuticals, food, petrochemicals, glass line reactors and columns, solvents, paints, and corrosive chemicals.

- It won’t contaminate anything near it because it’s non-corrosive, which is why the food industry uses it.

- It has no smell of its own.

Expanded PTFE:

100% virgin PTFE is the material used to produce expanded PTFE.

- Expanded PTFE can be highly compressible as a sealing material.

- It resists creep and cold flow.

- It can be easily adapted to the sealing surface.

- It can be modified according to the requirements of surface energy, stiffness, hardness, etc.

- It’s microporous, so it’s suitable for any task that requires airflow.

- It stretches in high heat and has a smooth texture.

- It is chemically inert, low pressure waterproof, UV resistant, low dielectric constant, radially extended, and has a level of divergent porosity.

- It can be used in the medical and biological industries, high-performance filters, medical devices, oil and gas industries, electrical insulators, hernia repair, vascular grafts and other reconstructive procedures, fluid purification applications, and environmental filtration.

In another word, both PTFE and expanded PTFE have excellent industrial applications and outstanding properties. But expanded PTFE has a wider range of applications than PTFE. The multidirectional fiber structure of expanded PTFE enables it to work under high surface pressure conditions. For the greatest safety requirements, such as flange sealing of oxygen-carrying tubes, expanded PTFE is a suitable material because it can be highly customized. Expanded PTFE performs better than PTFE. It is in so much demand in the market that it is now manufactured in different heights, densities, and sizes.

8. How to Choose the Right Gasket for Your Applications?

The correct gasket for your application is required to prevent failure. You should be aware that the gasket may fail if it is exposed to conditions that degrade the material. These are the key things to look out for when choosing a gasket.

1) Gasket material

Gaskets are available in a variety of materials. You must match materials to process requirements. For example, PTFE gaskets are designed for corrosive conditions and processes. Metal gaskets are used in petroleum industry systems.

2) Application

The choice of material needs to be aligned with the purpose or application. This means you should consider pressure, material, and temperature. The gasket material is suitable for the given temperature range. Therefore, you need to determine the operating temperature of the system. Additionally, the chemical composition of the fluid should determine the gasket material. Additionally, you should consider other factors such as oxidation, moisture content, and pH.

3) Gasket Type

After matching the material to the application, you need to select the appropriate type. Common varieties include solid gaskets, spiral wound gaskets, and jacketed gaskets. Jacketed washers are popular with metallic coatings and non-metallic interiors. Therefore, they improve damage resistance. Solid gaskets offer excellent durability but require higher compression forces to form a seal.

4) Gasket performance

It is recommended to test the performance of the gasket before use. For safety, parts should meet industry standards. These organizations also set test conditions to ensure the gaskets are safe to use. Ideally, test to ensure the gasket can withstand the pressures, chemicals, and temperatures of the process.

5) Gasket Manufacturer

You should make sure to find the right expanded PTFE gasket manufacturer. This is necessary to ensure you find a product that suits your needs. Consider a manufacturer with years of experience in making gaskets for different markets and industries. Make sure you find a manufacturer with testing, design, and inspection capabilities. In this way, you can ensure that the products you choose are reliable and of high quality.

Before you choose an expanded PTFE gasket, make sure it has been tested. In this way, you can ensure that it can meet the parameters required by your application. Tightness, compressibility, and temperature are important tests that must be performed. Additionally, you need to check the material’s ability to withstand chemical degradation.