High Performance Expanded PTFE Gasket

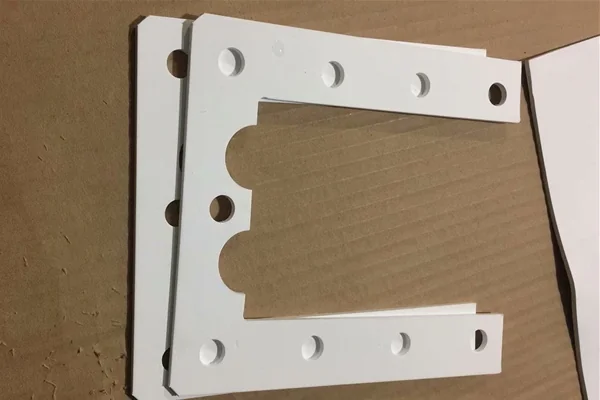

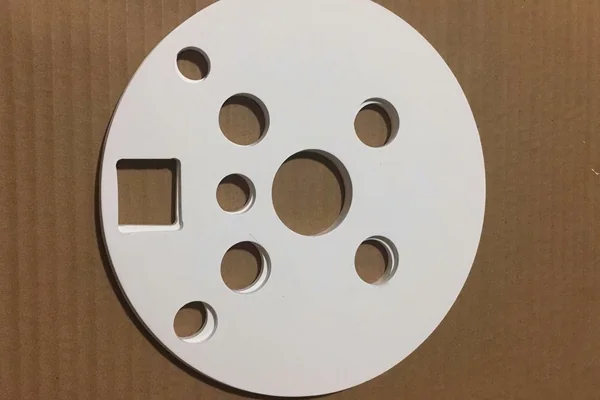

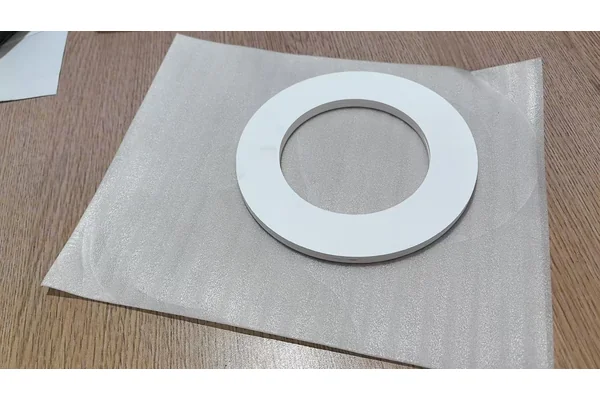

Expanded PTFE Gaskets are cut from 100% Expanded PTFE Sheets by the laser cutter or gasket die. They are a soft, flexible material with exceptional elasticity and conformability, capable of adapting to rough, irregular, or damaged flange surfaces. They have excellent sealability, chemical resistance, and reduce creep and cold flow. With excellent characteristics, expanded PTFE gasket is widely used for distillers, piping, and equipment in industries like chemical processing, Paper, oil and gas, and food & beverage.

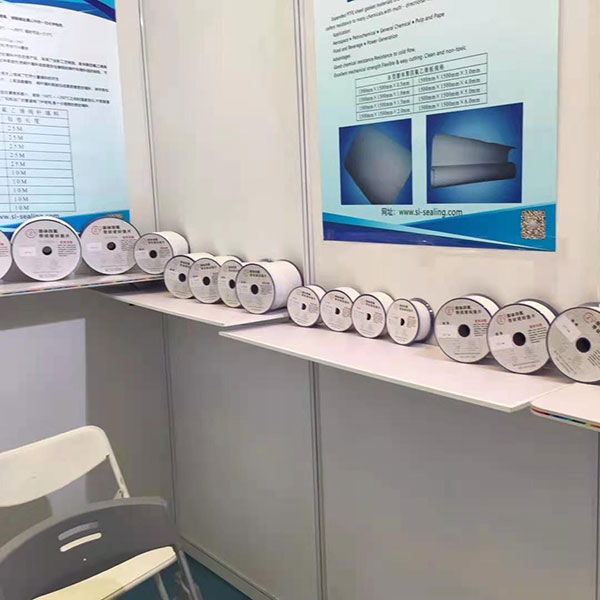

A monthly production capacity of 1,000 pcs of expanded PTFE sheets ensures that we have a sufficient and reliable supply of expanded PTFE gaskets.

| PROPERTY | STANDARD | VALUE |

| Color | – | White |

| Density | ASTM D792 | 0.70-0.9g/cm3 |

| Operating temperatures | – | -286 – 320°C |

| Compressibility | ASTM F36 | 45-50 % |

| Recovery | ASTM F36 | 10 -12% |

| Creep Relaxation | ASTM F38 | 35 – 36 % |

| Sealability (Nitrogen) | ASTM F 37B | 0.15 ml/hr |

| Sealability (Fuel A) | ASTM F 37B | 0.02 ml/hr |

| Service Pressure | – | Full Vacuum to 19 MPa |

| Tensile Strength Both directions | ASTM D638 | 19.6 MPa |

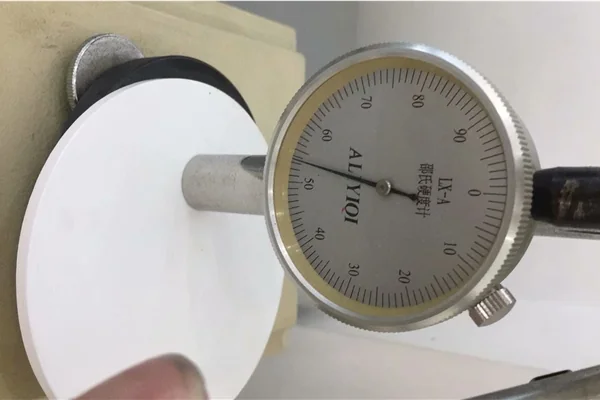

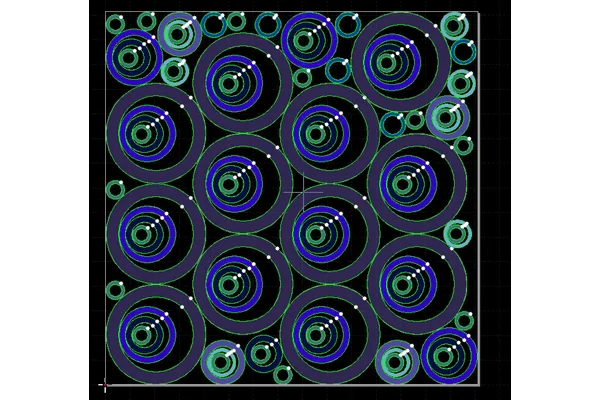

We produce expanded PTFE gasketing sheets by ourselves, allowing us to control both quality and cost from the source. We have advanced machinery and years of experience in expanded PTFE manufacturing, utilizing more efficient nesting and layout methods to produce gaskets. Our manufacturing process is highly efficient. All these distinctive characteristics ensure that we can maintain quality while controlling costs.

Expanded PTFE Gasket Manufacturers FAQ

1. What’s the Expanded PTFE Gasket Manufacturing Method?

2. Features of the Expanded PTFE Gasket

Expanded PTFE gaskets are known for the following technical features:

High resistance to creep and cold flow.

Excellent chemical compatibility across a wide pH range (0-14).

Good compressibility for easy installation and sealing.

Soft and flexible, easily adapting to irregular flange surfaces.

Available in various sizes, ranging from standard 1/2” to 24”, and customizable according to your requirements.

Compliant with FDA regulations, suitable for food and pharmaceutical applications.

3. Benefits of Using expanded PTFE gasket

Choosing expanded PTFE gaskets offers several practical benefits in sealing applications:

Reliable Chemical Resistance

Expanded PTFE gaskets effectively resist corrosion from aggressive chemicals, including acids, alkalis, and solvents.

Wide Temperature Range

Consistently stable sealing from -200°C to +260°C, suitable for extreme operating conditions.

Easy Installation and Maintenance

Easy to cut, punch, and install, this simplifies maintenance procedures and reduces downtime.

Long Service Life

Improved sealing reliability extends the service interval, helping control maintenance costs.

Multiple Application

Suitable for a wide range of flange types and sealing environments.

4. Advantages of Expanded PTFE Gaskets

Expanded PTFE gaskets offer several advantages, making them preferable in various industrial uses:

1. Chemical Compatibility

Expanded PTFE gaskets resist most industrial chemicals, making them ideal for environments involving aggressive substances.

2. Excellent Thermal Stability

They reliably withstand continuous thermal cycling without deformation, suited for applications in refineries, chemical plants, food processing, and pharmaceuticals.

3. Application Versatility

Expanded PTFE gaskets come in various densities, thicknesses, and configurations. Custom manufacturing can easily meet specific operational requirements.

4. Non-Corrosive and Hygienic

Non-toxic and non-reactive properties ensure safe use in sensitive industries like pharmaceutical and food production.

5. Ease of Use and Cost Efficiency

Their flexibility and ease of handling significantly simplify installation and replacement, reducing overall downtime.

5. Typical Industrial Applications of Expanded PTFE Gasket

Common Applications

Due to their exceptional properties, expanded PTFE gaskets are often used in:

Chemical & Petrochemical Plants

Sealing of reactors, pipelines, flanges, valves, and heat exchangers, preventing chemical leakage.

Pharmaceutical & Food Industries

FDA-approved sealing for sanitary equipment, ensuring compliance with hygiene standards.

Oil & Gas Facilities

Providing secure sealing in pipelines and equipment handling hydrocarbons and corrosive media.

Water Treatment Systems

Effective sealing in pumps, valves, and chemical dosing equipment.

Power Generation Equipment

Sealing solutions for turbines, compressors, and heat exchanger applications with variable temperatures and pressures.

Mechanical & Industrial Equipment: Reliable sealing to prevent ingress of dirt, grit, moisture, and contaminants into pumps, gearboxes, and rotating machinery.

Specific Applications:

Pump and Gearbox Seals: Prevents water ingress and corrosion, prolonging equipment lifespan.

Gearbox Protection: Effectively blocks sand and grit ingress, ideal for harsh environmental conditions.

Enhanced Coupling Efficiency: Improves sealing reliability between rotating equipment and storage tanks.

Corrosive Fluid Protection: Ensures hermetic sealing against aggressive chemical and alkaline solutions.

6. Comparing Pure PTFE and Expanded PTFE Materials

Pure PTFE ( Teflon):

Solid, chemically inert material

Temperature resistance up to 260°C

Corrosion-resistant, minimal friction

Non-contaminating, suitable for food processing and pharmaceuticals

Expanded PTFE (ePTFE)

Manufactured through the mechanical expansion of virgin PTFE

Soft, flexible, easy-to-compress sealing material

Excellence in resistance to creep and cold flow

The microporous structure is beneficial for filtration and breathable sealing

Wide use in medical, biological, and high-performance sealing applications

Customizable for specific sealing conditions (density, thickness, hardness)

While pure PTFE offers excellent chemical resistance, expanded PTFE provides superior sealing performance, flexibility, adaptability, and a widely applications.

7. Why Prefer an Expanded PTFE Gasket?

Expanded PTFE has excellent sealability due to its multidirectional fiber structure, which performs well under high surface pressure. This structural flexibility allows expanded PTFE to conform easily to irregularities, making it suitable for sealing critical applications like oxygen-carrying systems and aggressive chemical environments.

Moreover, expanded PTFE gaskets can be customized to meet specific performance demands, making them a highly customized sealing choice.

Our Expertise in Expanded PTFE Gaskets

Our team has many years of experience in manufacturing and supplying expanded PTFE solutions. The ePTFE gasket materials are produced by us, so we can control the quality and cost well. For detailed inquiries or customized solutions in expanded PTFE gaskets, please contact us directly.