In the sealing industry, the choice of gasket material can make or break operational success. Polytetrafluoroethylene (PTFE) gaskets are a popular solution, prized for their chemical resistance and versatility. Furthermore, expanded PTFE (ePTFE) and pure PTFE gaskets stand apart, each offering distinct advantages tailored to specific industrial challenges. Here, we explore their differences in composition, performance, and application, empowering sealing professionals to select the ideal solution for their needs.:

1. Material Composition and Structure

Expanded PTFE (ePTFE) Gaskets

Crafted from 100% pure expanded polytetrafluoroethylene, ePTFE gaskets undergo a specialized expansion process that yields a highly fibrillated, porous microstructure. This results in a soft, pliable material with exceptional elasticity and conformability, capable of adapting to rough, irregular, or damaged flange surfaces. Free of binders or additives, ePTFE maintains excellent purity and chemical stability, making it a premium choice for critical applications.

Pure PTFE Gaskets

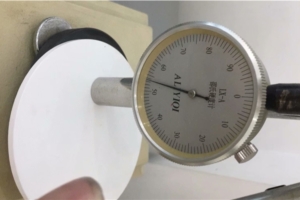

Fabricated from virgin PTFE resin through mechanical cutting, turning, or molding, pure PTFE gaskets offer a dense, rigid structure with a smooth finish. While this provides reliable performance on flat, uniform surfaces, their limited flexibility makes them less adaptable to imperfections or irregularities, positioning them as a practical option for conventional sealing needs.

2. Performance Characteristics

Expanded PTFE Gaskets

Sealing Excellence: ePTFE’s fibrous, multidirectional structure delivers superior sealing performance, particularly in low-pressure or moderate-temperature environments. Its ability to conform to imperfect surfaces ensures a tight, dependable seal where standard gaskets may falter.

Resistance to Creep and Cold Flow: The high-density fiber network minimizes creep and cold flow, common weaknesses in standard PTFE, offering enhanced mechanical stability over extended periods.

Chemical and Thermal Resilience: Virtually inert to all chemicals (except molten alkali metals and select extreme substances), ePTFE withstands temperatures up to 280°C, making it a robust choice for harsh conditions.

Ease of Use: Soft and flexible, ePTFE can be easily cut or punched into custom shapes, streamlining installation and reducing operational downtime.

Pure PTFE Gaskets

Dependable Sealing: Pure PTFE excels in routine industrial settings, providing solid sealing performance under stable conditions. However, it may struggle with significant pressure variations or uneven surfaces.

Creep and Cold Flow Vulnerability: In high-pressure or elevated-temperature scenarios, Pure PTFE is prone to deformation, potentially compromising long-term seal integrity.

Chemical and Thermal Properties: With excellent corrosion resistance and a temperature range of -100°C to 100°C (-148°F to 212°F), it performs well in moderate environments but falls short of ePTFE in extreme conditions.

Processing Versatility: Readily machined or molded, Pure PTFE is well-suited for standard flanges and straightforward applications

3. Application Suitability

Expanded PTFE Gaskets

Engineered for demanding conditions, ePTFE shines in high-temperature (up to 315°C), high-pressure, and highly corrosive environments. Its adaptability to rough or irregular surfaces makes it indispensable in industries like chemical processing, oil and gas, pharmaceuticals, and food production, where reliability and longevity are non-negotiable.

Pure PTFE Gaskets

Cost-effective and widely available, pure PTFE is ideal for low-pressure, low-temperature, and non-corrosive settings, such as standard pipeline flanges. It’s a go-to solution for general industrial use where extreme performance isn’t required

4. Advantages and Limitations

Expanded PTFE Gaskets

Advantages: Exceptional sealing, resistance to creep and cold flow, outstanding conformability, and durability in aggressive conditions.

Limitations: Higher cost relative to pure PTFE.

Pure PTFE Gaskets

Advantages: Affordable, readily available, and effective for everyday sealing tasks.

Limitations: Reduced performance under high pressure, high temperature, or on irregular surfaces; susceptible to creep and cold flow

5. Choosing the Right Gasket for Your Application

Opt for Expanded PTFE Gaskets when your operation involves:

Temperatures up to 280°C

High-pressure systems

Aggressive chemical exposure

Select Pure PTFE Gaskets for:

Low-pressure and low-temperature conditions

Mild or non-corrosive environments

Standard flange connections

Conclusion: Precision Sealing Starts with the Right Choice

Expanded PTFE and pure PTFE gaskets each have their advantages. ePTFE offers excellent performance and adaptability for a wide applications, while pure PTFE delivers cost-effective reliability for common needs.

Ready to get more expanded PTFE gaskets information? Contact our team:info@nbseals.com today for more professional recommendations.

.