Polytetrafluoroethylene (PTFE) is a fluoropolymer renowned for its exceptional chemical resistance and ultra-high purity. PTFE sheet and rod exhibit self-lubricating behavior and a very low coefficient of friction, making them ideal for high-temperature seals, insulators, and bearings in semiconductor, aerospace, and chemical-processing environments.

PTFE’s low friction also suits sliding components—plain bearings, gears, and glide plates—where it typically outperforms nylon and acetal (POM) and is comparable to UHMW-PE, while operating over a wider temperature range: −100 °F to +400 °F (−73 °C to 204 °C) and providing excellent dielectric insulation. Although PTFE’s mechanical strength is lower than that of some engineering plastics, it can be reinforced with fillers such as carbon, graphite, bronze, and glass fiber.

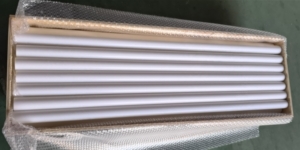

Key Features of Virgin PTFE Rod

Lowest coefficient of friction among common engineering plastics

Maximum service temperature up to 500 °F

Exceptional chemical resistance

Excellent thermal and electrical insulation

Limitations: Lower compressive and tensile strength compared with many engineering plastics.

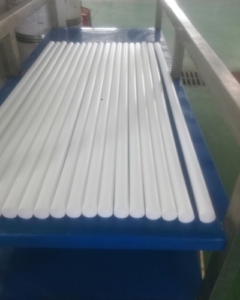

Why Anneal PTFE Bars?

Annealing is a heat-treatment process that alters a material’s physical (and sometimes chemical) state to improve ductility and reduce hardness, making it easier to machine and more dimensionally stable. The process involves heating above the recrystallization region, soaking at a temperature, then controlled cooling—relaxing internal stresses and stabilizing the microstructure.

Benefits of Annealed PTFE Bars

Higher dimensional stability: Reduced risk of warp/shrink after machining and during service

Improved tensile consistency: Better mechanical performance, especially under load

Lower deformation at elevated temperature: Better resistance to creep/Cold flow

Enhanced processability: More predictable machining and tighter tolerances

Annealed PTFE Bars Characteristics

Corrosion resistance: Inert to nearly all acids, bases, salts, and organic solvents; only molten sodium and liquid fluorine will attack PTFE.

Temperature range: −180 °C to +300 °C with tolerance for rapid thermal cycling.

Electrical insulation: Suitable for high-temperature, high-voltage insulating components.

Regular Sizes

Standard diameters include 15 mm, 18 mm, 20 mm, 22 mm, 30 mm, etc. Custom diameters/lengths and machined-to-print parts are available on request.

Where Annealed PTFE Bars Are Used

Chemical Industry

Corrosion-resistant parts: Valve components, pump elements, reactor linings—stable in strong acids/alkalis.

Mechanical Engineering

Self-lubricating parts: Bearings, piston rings, guides—reduce friction and wear, lower energy consumption.

Wear components: Wear plates, seal rings—extend equipment life.

Electronics & Electrical

Insulation: Cable jacketing, PCB base components—prevent current leakage at elevated temperatures.

Medical & Food Equipment

Medical devices: Components where non-toxicity and heat resistance are critical.

Food-contact tooling: Molds, conveyor elements—support hygienic, easy-to-clean designs.

Aerospace

High-temperature insulators & seals: Maintain performance under extreme thermal conditions.

Choose annealed PTFE bars when your design prioritizes:

Tight tolerances and post-machining stability

High-temperature service with minimal deformation

Low friction and chemical inertness in aggressive media

Reliable insulation in high-voltage or high-frequency environments