Description

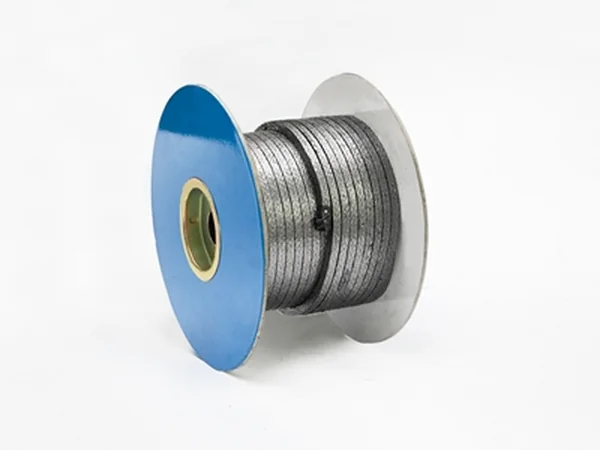

Expanded graphite packing is ideal for industries where effective sealing is critical, especially in high-pressure, high-temperature, and chemically aggressive environments. Due to its excellent thermal, chemical, and mechanical properties, expanded graphite packing is widely used in industrial sealing applications. Expanded graphite packing has a variety of types after being reinforced with other fibers or braided with other materials. including Graphite packing reinforced with metal wire, Graphite Packing with PFFE impregnation, graphite packing with PTFE corner, graphite packing with carbon fiber corner.

Feature

Low Friction: Protects shafts and stems from wear.

Thermal Conductivity: Efficient heat dissipation.

Chemical Resistance: Suitable for harsh chemical environments.

Elasticity: Maintains sealing performance under dynamic conditions.

Corrosion Protection: Optional corrosion inhibitor (e.g., zinc powder) for added protection.

Application

Graphite packing can be suitable for a wide range of industrial applications.

Common Used for Valves, pumps, expansion joints, mixers, and agitators. High-pressure and high-temperature environments. and hydrocarbon processing, pulp and paper, power stations, refineries, and more industries: