-

The Expanded PTFE Valve Stem Packing provides absolute reliability, chemical resistance, and the lowest total cost of ownership. It is an economical alternative to a sheet gasket for large equipment flanges. The regular sizes include the diameters of 6,8,10,12,14mm, length can be 20m, 25m, 30m, 50m,100m, etc

The Expanded PTFE Valve Stem Packing provides absolute reliability, chemical resistance, and the lowest total cost of ownership. It is an economical alternative to a sheet gasket for large equipment flanges. The regular sizes include the diameters of 6,8,10,12,14mm, length can be 20m, 25m, 30m, 50m,100m, etc -

Graphite sheet is selected from the high purity flake graphite. They can be reinforced by metal mesh, foil, or tanged metal. They are made through chemical treatment, expanded under high temperature, and then rolling. It offers excellent sealing capabilities under extreme conditions with a longer life and less maintenance.

Graphite sheet is selected from the high purity flake graphite. They can be reinforced by metal mesh, foil, or tanged metal. They are made through chemical treatment, expanded under high temperature, and then rolling. It offers excellent sealing capabilities under extreme conditions with a longer life and less maintenance. -

Fibreglass cloth is woven by continuous texturized glass fibre yarns, including C-glass and E-glass. Its woven styles include plain-woven and twill woven, according to different applications and requirements. It feels soft, smooth and compact. The surface can be foiled with aluminium or treated with silicon, vermiculite and PTFE, etc.

Fibreglass cloth is woven by continuous texturized glass fibre yarns, including C-glass and E-glass. Its woven styles include plain-woven and twill woven, according to different applications and requirements. It feels soft, smooth and compact. The surface can be foiled with aluminium or treated with silicon, vermiculite and PTFE, etc. -

Glass fiber packing is ideal organic and inorganic fiber as a replacement of asbestos. It is braided from E-glass fiber impregnated with PTFE. The packing has many excellent characteristics such as high strength, high-temperature resistance, low density, low thermal conductivity, good insulation, and non-ignitibility, etc. Glass fiber packing without any impregnation and Glass fiber packing impregnated with graphite are also available.

Glass fiber packing is ideal organic and inorganic fiber as a replacement of asbestos. It is braided from E-glass fiber impregnated with PTFE. The packing has many excellent characteristics such as high strength, high-temperature resistance, low density, low thermal conductivity, good insulation, and non-ignitibility, etc. Glass fiber packing without any impregnation and Glass fiber packing impregnated with graphite are also available. -

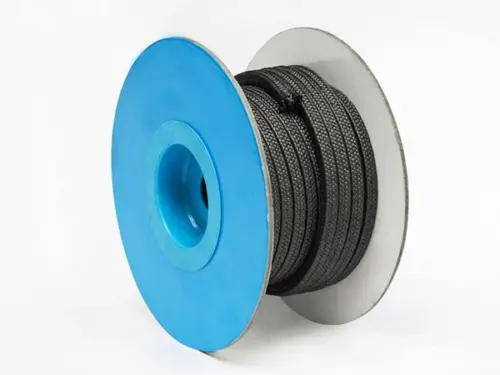

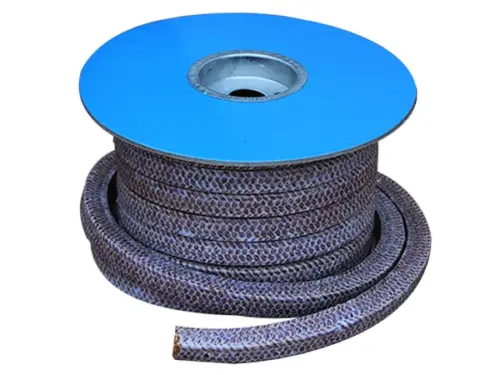

Graphite PTFE (GFO) braided packing, also known as Black PTFE Packing, is a high-performance sealing material made from braided PTFE yarn uniformly embedded with graphite particles. Its versatility and reliability make it an excellent choice for demanding sealing applications. and it is designed to provide exceptional sealing performance in demanding industrial applications.

Graphite PTFE (GFO) braided packing, also known as Black PTFE Packing, is a high-performance sealing material made from braided PTFE yarn uniformly embedded with graphite particles. Its versatility and reliability make it an excellent choice for demanding sealing applications. and it is designed to provide exceptional sealing performance in demanding industrial applications. -

Graphite PTFE Packing with Aramid Fiber Corner is a high-performance composite sealing material. It utilizes PTFE-impregnated aramid fibers as corner reinforcement, combined with high-quality graphite PTFE(black PTFE) yarn as the main sealing body, processed through a specialized braiding technique. This structure retains the high strength of aramid fibers while integrating the low friction, corrosion resistance, and excellent thermal conductivity of graphite PTFE, making it ideal for dynamic sealing in high-speed, high-pressure, and highly corrosive conditions

Graphite PTFE Packing with Aramid Fiber Corner is a high-performance composite sealing material. It utilizes PTFE-impregnated aramid fibers as corner reinforcement, combined with high-quality graphite PTFE(black PTFE) yarn as the main sealing body, processed through a specialized braiding technique. This structure retains the high strength of aramid fibers while integrating the low friction, corrosion resistance, and excellent thermal conductivity of graphite PTFE, making it ideal for dynamic sealing in high-speed, high-pressure, and highly corrosive conditions -

Kammprofile gasket consists of a concentrically serrated solid metal core with a soft conformable sealing layer bonded to each face. The layer can be expanded graphite, ptfe, asbesots free gasket sheeting material or some soft metal. It features excellent compressibility and good recovery characteristics. The gasket mainly suits for vacuum and extremely high pressure applications. It can an be refurbished and reused and has better leak tightness than spiral wound gaskets.

Kammprofile gasket consists of a concentrically serrated solid metal core with a soft conformable sealing layer bonded to each face. The layer can be expanded graphite, ptfe, asbesots free gasket sheeting material or some soft metal. It features excellent compressibility and good recovery characteristics. The gasket mainly suits for vacuum and extremely high pressure applications. It can an be refurbished and reused and has better leak tightness than spiral wound gaskets. -

Kynol Fiber Packing Braided (also called GOLDEN ARAMID Packing) is a high-performance sealing material made from Kynol (Novilid or Phenolic) fibers and impregnated with PTFE lubricant. This material combines excellent mechanical properties, flexibility, and strength, making it suitable for various industrial applications.

Kynol Fiber Packing Braided (also called GOLDEN ARAMID Packing) is a high-performance sealing material made from Kynol (Novilid or Phenolic) fibers and impregnated with PTFE lubricant. This material combines excellent mechanical properties, flexibility, and strength, making it suitable for various industrial applications. -

Metal Jacketed Gasket is a thin metallic outer jacket that encloses a compressible, flexible filler. The metal case protects the filler from pressure, temperature, and corrosion while allowing the gasket to tolerate minor flange irregularities. The Metal Jacketed Gaskets are made in many styles to suit the most demanding applications: Single-Jacketed – Jacket covers one sealing face plus ID/OD. Double-Jacketed – Two-piece jacket fully encloses ID, OD, and both sealing faces. Use: heat exchangers, corrosive or higher-temperature service. French Type Jacketed– Jacket folded around a soft core with exposed filler at the edge; economical. Double Jacketed Corrugated – Corrugated metal element used as filler or as a solid corrugated core to increase resiliency. Single Jacketed Overlap– Enhanced jacket integrity and leak resistance on the periphery. Pass/Partition Bars – Integral or welded ribs (preferred for best seal). Any layout available.

Metal Jacketed Gasket is a thin metallic outer jacket that encloses a compressible, flexible filler. The metal case protects the filler from pressure, temperature, and corrosion while allowing the gasket to tolerate minor flange irregularities. The Metal Jacketed Gaskets are made in many styles to suit the most demanding applications: Single-Jacketed – Jacket covers one sealing face plus ID/OD. Double-Jacketed – Two-piece jacket fully encloses ID, OD, and both sealing faces. Use: heat exchangers, corrosive or higher-temperature service. French Type Jacketed– Jacket folded around a soft core with exposed filler at the edge; economical. Double Jacketed Corrugated – Corrugated metal element used as filler or as a solid corrugated core to increase resiliency. Single Jacketed Overlap– Enhanced jacket integrity and leak resistance on the periphery. Pass/Partition Bars – Integral or welded ribs (preferred for best seal). Any layout available.