-

PTFE Rod has Extruded or Molded two types. Molded/Extruded PTFE Rod produced from 100% PTFE virgin PTFE materials, it has the lowest coefficient of friction of all kinds of solid materials and the best electrical properties of all plastics. They are the ideal elements for the food industry. PTFE tube made from 100% PTFE virgin PTFE material, it is suitable for use as machining stock for all kinds of chemical, electrical, mechanical components

PTFE Rod has Extruded or Molded two types. Molded/Extruded PTFE Rod produced from 100% PTFE virgin PTFE materials, it has the lowest coefficient of friction of all kinds of solid materials and the best electrical properties of all plastics. They are the ideal elements for the food industry. PTFE tube made from 100% PTFE virgin PTFE material, it is suitable for use as machining stock for all kinds of chemical, electrical, mechanical components -

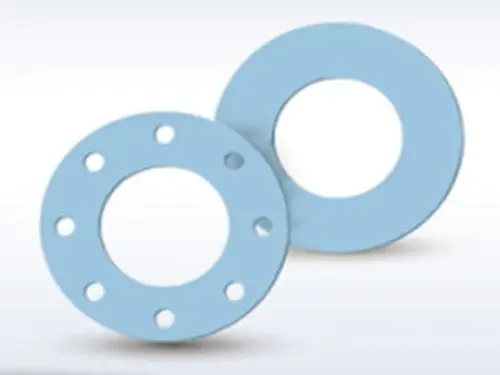

Expanded PTFE Gasket is made by expanding PTFE; it is expanded through a unique process into a microstructure that enhances its compressibility, flexibility, and resistance to harsh conditions. It is suitable for use in steel flanges and flanges where a highly compressible gasket is required. And it's also ideal for sealing flanges with irregular surfaces. It will not exhibit the cold flow problems associated with virgin PTFE or the hardness problems of some other filled PTFE products. With the feature of excellent sealability, cuts easily, and separates cleanly from flanges after use, the flexibility of the expanded PTFE gasket's unique material allows it to fit any flange shape.

Expanded PTFE Gasket is made by expanding PTFE; it is expanded through a unique process into a microstructure that enhances its compressibility, flexibility, and resistance to harsh conditions. It is suitable for use in steel flanges and flanges where a highly compressible gasket is required. And it's also ideal for sealing flanges with irregular surfaces. It will not exhibit the cold flow problems associated with virgin PTFE or the hardness problems of some other filled PTFE products. With the feature of excellent sealability, cuts easily, and separates cleanly from flanges after use, the flexibility of the expanded PTFE gasket's unique material allows it to fit any flange shape. -

The Modified PTFE for use as a gasket material with strong chemical resistance properties and designed for severe chemical service, color-coded for easy identification, superior seal-ability, which helps reduce process and media loss as well as fugitive emissions, reduced creep, and cold flow characteristics. The different combination offers a variety of different properties as the following sheet.

The Modified PTFE for use as a gasket material with strong chemical resistance properties and designed for severe chemical service, color-coded for easy identification, superior seal-ability, which helps reduce process and media loss as well as fugitive emissions, reduced creep, and cold flow characteristics. The different combination offers a variety of different properties as the following sheet. -

PTFE Bonded EPDM gasket is produced with high-quality EPDM rubber and PTFE for maximum chemical and corrosion resistance. They are suitable for fiberglass, glass-lined, and steel full-face flanges. The gaskets have Low bolt torque with superior sealing, Dual, Concentric, Convex sealing rings; They will eliminate cracked flanges, reducing installation costs, while maintaining high performance. It is ideal for plastic piping systems, as well as metal or plastic-lined metal systems. Standards: ASME (ANSI) B16.5, JIS 10K, DIN2501 PN10/PN16, SABS1123, BS4504 etc

PTFE Bonded EPDM gasket is produced with high-quality EPDM rubber and PTFE for maximum chemical and corrosion resistance. They are suitable for fiberglass, glass-lined, and steel full-face flanges. The gaskets have Low bolt torque with superior sealing, Dual, Concentric, Convex sealing rings; They will eliminate cracked flanges, reducing installation costs, while maintaining high performance. It is ideal for plastic piping systems, as well as metal or plastic-lined metal systems. Standards: ASME (ANSI) B16.5, JIS 10K, DIN2501 PN10/PN16, SABS1123, BS4504 etc -

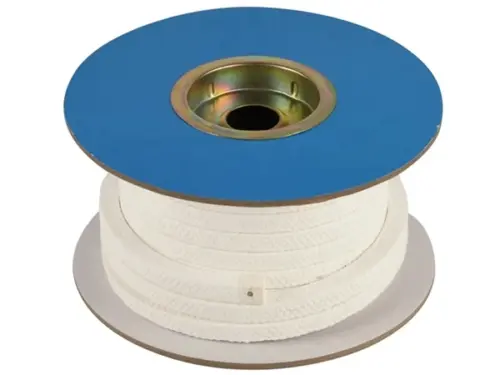

Expanded PTFE joint sealant is a new soft seal tape product made of 100% PTFE, developed using a highly specific treatment on the PTFE Fluorocarbon material. It excels in sealing flange connections, especially those with surface irregularities commonly found in glass-lined or plastic-lined equipment. The Seal tape is a form-in-place gasket with its exceptional performance characteristics, pure material composition, and versatility, serving as an ideal sealing solution across various industries. Its adaptability and ease of use contribute to its pivotal role in diverse applications, making it a reliable choice for sealing requirements in different industrial settings. The ePTFE Joint Sealant Tape comes with a backing adhesive on one side, which allows custom on-site cutting and shaping without the need for pre-cutting or prefabrication.

Expanded PTFE joint sealant is a new soft seal tape product made of 100% PTFE, developed using a highly specific treatment on the PTFE Fluorocarbon material. It excels in sealing flange connections, especially those with surface irregularities commonly found in glass-lined or plastic-lined equipment. The Seal tape is a form-in-place gasket with its exceptional performance characteristics, pure material composition, and versatility, serving as an ideal sealing solution across various industries. Its adaptability and ease of use contribute to its pivotal role in diverse applications, making it a reliable choice for sealing requirements in different industrial settings. The ePTFE Joint Sealant Tape comes with a backing adhesive on one side, which allows custom on-site cutting and shaping without the need for pre-cutting or prefabrication. -

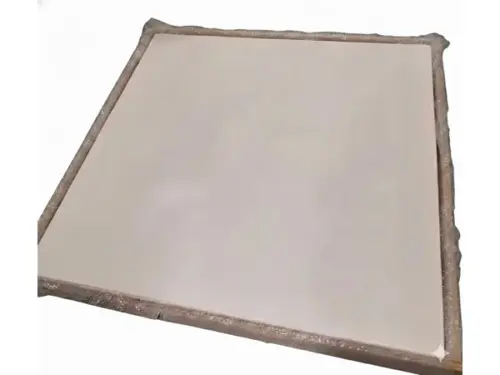

Expanded PTFE Sheets are made from 100% virgin PTFE resins. A special process produces a uniform and highly fibrillated microstructure with many fibers running in multiple directions. It is a food-approved product and has excellent resistance to a wide range of chemicals, making it a popular sealing material in the food, drink, and pharmaceutical industries. It also has excellent sealability, cuts easily, and separates cleanly from flanges after use.

Expanded PTFE Sheets are made from 100% virgin PTFE resins. A special process produces a uniform and highly fibrillated microstructure with many fibers running in multiple directions. It is a food-approved product and has excellent resistance to a wide range of chemicals, making it a popular sealing material in the food, drink, and pharmaceutical industries. It also has excellent sealability, cuts easily, and separates cleanly from flanges after use. -

Modified PTFE sheets improved performance over conventional PTFE, Reduced product loss, and emissions. Excellent bolt torque retention, unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE Sheets. Withstands a wide range of chemicals for extended service life in a wide variety of applications.

Modified PTFE sheets improved performance over conventional PTFE, Reduced product loss, and emissions. Excellent bolt torque retention, unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE Sheets. Withstands a wide range of chemicals for extended service life in a wide variety of applications. -

We have plenty of experience to produce many types of Rubber Parts by OEM or ODM, such as seals flinger, wiper, rubber hood latch, rubber bumper, seal drum, latch hood rubber, Gland half packing, and so on. They are mainly used as replacement applications for all industries. We could custom-produce accordingly to the drawings or samples.

We have plenty of experience to produce many types of Rubber Parts by OEM or ODM, such as seals flinger, wiper, rubber hood latch, rubber bumper, seal drum, latch hood rubber, Gland half packing, and so on. They are mainly used as replacement applications for all industries. We could custom-produce accordingly to the drawings or samples.

-

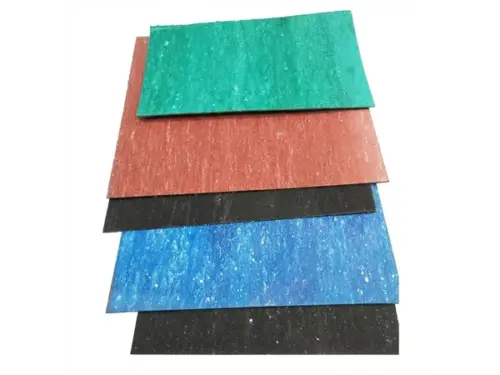

The non-asbestos compressed sheet is made from aramid/kevlar fiber, natural rubber, heat-resisting packing material, and dye, compressed and calendered under high temperature and pressure into a sheet form. It eliminates the asbestos-rubber sheet essentially and thoroughly. Substitution of corresponding models of asbestos rubber sheet, Used for the equipment in water, high-temperature steam, compressed air, valve, heat exchanger etc. and used as sealing material in the joints of the pipeline. It can be used in the food and medical industry

The non-asbestos compressed sheet is made from aramid/kevlar fiber, natural rubber, heat-resisting packing material, and dye, compressed and calendered under high temperature and pressure into a sheet form. It eliminates the asbestos-rubber sheet essentially and thoroughly. Substitution of corresponding models of asbestos rubber sheet, Used for the equipment in water, high-temperature steam, compressed air, valve, heat exchanger etc. and used as sealing material in the joints of the pipeline. It can be used in the food and medical industry -

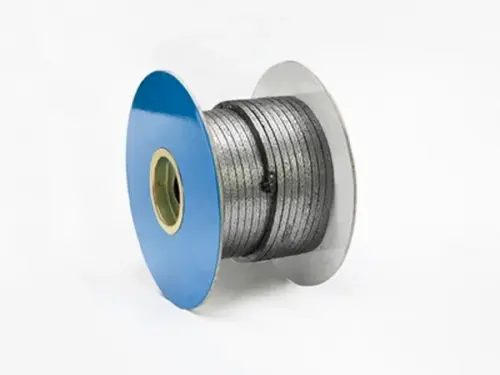

Pure PTFE Yarn is used to braid Pure PTFE Packing, available with Pure PTFE Yarn and PTFE Yarn with oil two types. Other yarns for braid packing are available, such as graphite yarn, GFO yarn, Ramie Yarn, Acrylic yarn, Kevlar Yarn, Carbon fiber yarn, Glass /Ceramic fiber and asbestos yarn etc Raw materials.

Pure PTFE Yarn is used to braid Pure PTFE Packing, available with Pure PTFE Yarn and PTFE Yarn with oil two types. Other yarns for braid packing are available, such as graphite yarn, GFO yarn, Ramie Yarn, Acrylic yarn, Kevlar Yarn, Carbon fiber yarn, Glass /Ceramic fiber and asbestos yarn etc Raw materials. -

Rubber sheets are manufactured for your different requirements such as oil-resisting, acid, and alkali-resisting, cold and heat-resisting, insulation, anti-seismic, etc. They can cut into various gaskets, used in chemicals, elections, fire-resisting, and food. They also can be used as a sealer, buffer rubber ring, rubber mat, sealing strip, and for the decoration of flights of step and ground of hotel, port boats, and ships, vehicles, etc. The materials are available in various kinds such as NBR, SBR, EPDM, Silicone, NR, Viton, etc.

Rubber sheets are manufactured for your different requirements such as oil-resisting, acid, and alkali-resisting, cold and heat-resisting, insulation, anti-seismic, etc. They can cut into various gaskets, used in chemicals, elections, fire-resisting, and food. They also can be used as a sealer, buffer rubber ring, rubber mat, sealing strip, and for the decoration of flights of step and ground of hotel, port boats, and ships, vehicles, etc. The materials are available in various kinds such as NBR, SBR, EPDM, Silicone, NR, Viton, etc. -

Spiral Wound Gasket consists of a thin metal hoop and non-metallic filler material that is simultaneously wound. The metal hoop is pre-formed in V or W-shaped profile, which allows the gasket to act as a spring between the flanges. Spiral Wound Gaskets are extremely popular due to the wide variety of available styles and sizes, it is the precision-engineered solution for flange joints, manholes, and other high-temperature, high-pressure applications. We can produce according to ASME, BS, JIS, and EN(DIN) standards or client requests.

Spiral Wound Gasket consists of a thin metal hoop and non-metallic filler material that is simultaneously wound. The metal hoop is pre-formed in V or W-shaped profile, which allows the gasket to act as a spring between the flanges. Spiral Wound Gaskets are extremely popular due to the wide variety of available styles and sizes, it is the precision-engineered solution for flange joints, manholes, and other high-temperature, high-pressure applications. We can produce according to ASME, BS, JIS, and EN(DIN) standards or client requests. -

Ring Joint Gaskets are machined from a variety of types forged solid metal such as Soft iron, ANSI304, ANSI316, F5, Low carbon, and special materials of alloy metals, Inconel Duplex, Monel, Hastelloy, Titanium, etc. They are designed for high pressure and temperature applications by selecting the suitable shape and material. The hardness of the RTJ gasket body should always be 20-30HB less than the hardness of the flanges to prevent flange deformation.

Ring Joint Gaskets are machined from a variety of types forged solid metal such as Soft iron, ANSI304, ANSI316, F5, Low carbon, and special materials of alloy metals, Inconel Duplex, Monel, Hastelloy, Titanium, etc. They are designed for high pressure and temperature applications by selecting the suitable shape and material. The hardness of the RTJ gasket body should always be 20-30HB less than the hardness of the flanges to prevent flange deformation. -

Kammprofile gasket consists of a concentrically serrated solid metal core with a soft conformable sealing layer bonded to each face. The layer can be expanded graphite, ptfe, asbesots free gasket sheeting material or some soft metal. It features excellent compressibility and good recovery characteristics. The gasket mainly suits for vacuum and extremely high pressure applications. It can an be refurbished and reused and has better leak tightness than spiral wound gaskets.

Kammprofile gasket consists of a concentrically serrated solid metal core with a soft conformable sealing layer bonded to each face. The layer can be expanded graphite, ptfe, asbesots free gasket sheeting material or some soft metal. It features excellent compressibility and good recovery characteristics. The gasket mainly suits for vacuum and extremely high pressure applications. It can an be refurbished and reused and has better leak tightness than spiral wound gaskets. -

Metal Jacketed Gasket is a thin metallic outer jacket that encloses a compressible, flexible filler. The metal case protects the filler from pressure, temperature, and corrosion while allowing the gasket to tolerate minor flange irregularities. The Metal Jacketed Gaskets are made in many styles to suit the most demanding applications: Single-Jacketed – Jacket covers one sealing face plus ID/OD. Double-Jacketed – Two-piece jacket fully encloses ID, OD, and both sealing faces. Use: heat exchangers, corrosive or higher-temperature service. French Type Jacketed– Jacket folded around a soft core with exposed filler at the edge; economical. Double Jacketed Corrugated – Corrugated metal element used as filler or as a solid corrugated core to increase resiliency. Single Jacketed Overlap– Enhanced jacket integrity and leak resistance on the periphery. Pass/Partition Bars – Integral or welded ribs (preferred for best seal). Any layout available.

Metal Jacketed Gasket is a thin metallic outer jacket that encloses a compressible, flexible filler. The metal case protects the filler from pressure, temperature, and corrosion while allowing the gasket to tolerate minor flange irregularities. The Metal Jacketed Gaskets are made in many styles to suit the most demanding applications: Single-Jacketed – Jacket covers one sealing face plus ID/OD. Double-Jacketed – Two-piece jacket fully encloses ID, OD, and both sealing faces. Use: heat exchangers, corrosive or higher-temperature service. French Type Jacketed– Jacket folded around a soft core with exposed filler at the edge; economical. Double Jacketed Corrugated – Corrugated metal element used as filler or as a solid corrugated core to increase resiliency. Single Jacketed Overlap– Enhanced jacket integrity and leak resistance on the periphery. Pass/Partition Bars – Integral or welded ribs (preferred for best seal). Any layout available. -

The corrugated metal gaskets can be direct replacements for spiral wound gaskets. It can eliminate inward buckling issues while creating a seal at moderate flange stresses. Corrugated metal is covered with graphite, ceramic, or PTFE layer. An additional finishing layer is applied depending on the requirements of the medium to be sealed. The gaskets with a soft layer on both sides are used in low-pressure applications in large diameter flue gas ducts at high temperatures

The corrugated metal gaskets can be direct replacements for spiral wound gaskets. It can eliminate inward buckling issues while creating a seal at moderate flange stresses. Corrugated metal is covered with graphite, ceramic, or PTFE layer. An additional finishing layer is applied depending on the requirements of the medium to be sealed. The gaskets with a soft layer on both sides are used in low-pressure applications in large diameter flue gas ducts at high temperatures -

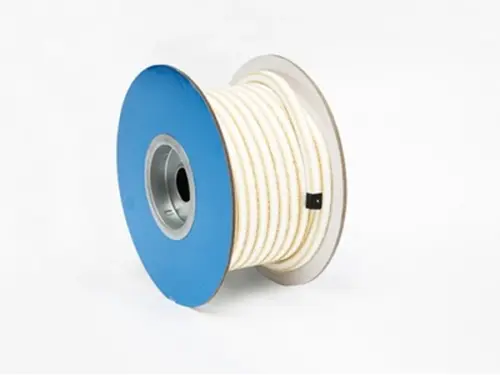

Pure PTFE Packing is a pure PTFE fiber yarn braided into the square cross-section and impregnated with PTFE dispersion. High cross-sectional density and structural strength. It is designed for valves and lower shaft speed application under medial pressure in food processing, pharmaceuticals, paper mills, fiber plants where high purity and corrosion resistance is required. PTFE packing can be also treated with lubrication, it is an economic type.

Pure PTFE Packing is a pure PTFE fiber yarn braided into the square cross-section and impregnated with PTFE dispersion. High cross-sectional density and structural strength. It is designed for valves and lower shaft speed application under medial pressure in food processing, pharmaceuticals, paper mills, fiber plants where high purity and corrosion resistance is required. PTFE packing can be also treated with lubrication, it is an economic type. -

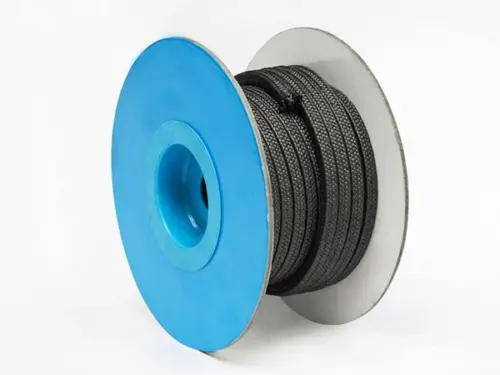

Graphite PTFE (GFO) braided packing, also known as Black PTFE Packing, is a high-performance sealing material made from braided PTFE yarn uniformly embedded with graphite particles. Its versatility and reliability make it an excellent choice for demanding sealing applications. and it is designed to provide exceptional sealing performance in demanding industrial applications.

Graphite PTFE (GFO) braided packing, also known as Black PTFE Packing, is a high-performance sealing material made from braided PTFE yarn uniformly embedded with graphite particles. Its versatility and reliability make it an excellent choice for demanding sealing applications. and it is designed to provide exceptional sealing performance in demanding industrial applications. -

Aramid PTFE Braided Packing is braided from quality Aramid(Kevlar)yarns, which are uniformly impregnated with PTFE dispersion. The braided packing shows good chemical resistance, high elasticity, and very low cold flow. It is wear-resistant but may damage the shaft if not used properly. The aramid fiber can be braided in many types for different applications, such as Aramid PTFE Packing with lubricant for a slurry service application, Spun aramid fiber packing with economical use; PTFE packing with Aramid corner, Graphite PTFE Packing with Aramid Corner, GPTFE & Aramid in Zebra braided packing, etc.

Aramid PTFE Braided Packing is braided from quality Aramid(Kevlar)yarns, which are uniformly impregnated with PTFE dispersion. The braided packing shows good chemical resistance, high elasticity, and very low cold flow. It is wear-resistant but may damage the shaft if not used properly. The aramid fiber can be braided in many types for different applications, such as Aramid PTFE Packing with lubricant for a slurry service application, Spun aramid fiber packing with economical use; PTFE packing with Aramid corner, Graphite PTFE Packing with Aramid Corner, GPTFE & Aramid in Zebra braided packing, etc. -

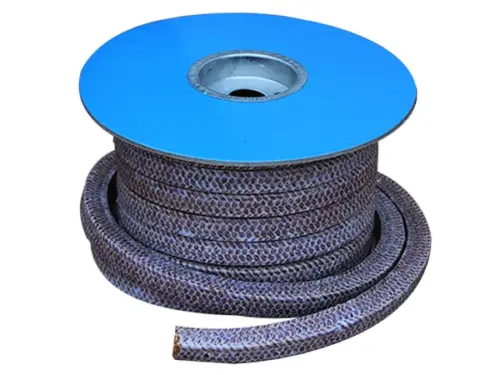

Carbonized fiber packing is braided from oxidized PAN fiber impregnated with PTFE, silicon-oil-free. Compared with traditional carbonized fiber packing, it is not brittle and suitable for high peripheral speed applications. With the high strength and good thermal conductivity of the PAN fiber, and excellent self-lubrication of the PTFE, the packing has a long life and does not damage shafts. The related carbon fiber packing for a different purpose is available, such as Carbonized fiber packing with graphite, Carbonized Fiber Packing Reinforced with Nickel wire, Carbon fiber packing.

Carbonized fiber packing is braided from oxidized PAN fiber impregnated with PTFE, silicon-oil-free. Compared with traditional carbonized fiber packing, it is not brittle and suitable for high peripheral speed applications. With the high strength and good thermal conductivity of the PAN fiber, and excellent self-lubrication of the PTFE, the packing has a long life and does not damage shafts. The related carbon fiber packing for a different purpose is available, such as Carbonized fiber packing with graphite, Carbonized Fiber Packing Reinforced with Nickel wire, Carbon fiber packing. -

Acrylic PTFE Packing is braided from high strength acrylic synthetic yarns with PTFE impregnated twice. The Acrylic PTFE packing has excellent properties of tightness, lubricity, and good resistance to chemicals. Wide variety of uses throughout a plant. Used in pumps and valves, it can handle most chemicals except strong acid, strong alkali, and a strong oxidizer. Especially for the condition of middle temperature, high pressure, high speed, and where contamination is not permitted.

Acrylic PTFE Packing is braided from high strength acrylic synthetic yarns with PTFE impregnated twice. The Acrylic PTFE packing has excellent properties of tightness, lubricity, and good resistance to chemicals. Wide variety of uses throughout a plant. Used in pumps and valves, it can handle most chemicals except strong acid, strong alkali, and a strong oxidizer. Especially for the condition of middle temperature, high pressure, high speed, and where contamination is not permitted. -

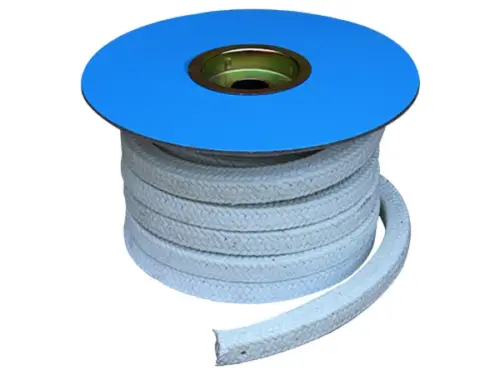

Ramie Fiber packing is made of high-quality ramie fiber, impregnated with light-colored, special PTFE and lubricant during square plaiting operation.it is not harsh on shafts and stems. It is widely used for kinds of pumps, refinery equipment, filters, valves, etc. It is also available with Ramie fiber packing with silicon rubber core,high-elasticity silicone core absorbs vibration, improves sealing, and controls leakage.

Ramie Fiber packing is made of high-quality ramie fiber, impregnated with light-colored, special PTFE and lubricant during square plaiting operation.it is not harsh on shafts and stems. It is widely used for kinds of pumps, refinery equipment, filters, valves, etc. It is also available with Ramie fiber packing with silicon rubber core,high-elasticity silicone core absorbs vibration, improves sealing, and controls leakage. -

Glass fiber packing is ideal organic and inorganic fiber as a replacement of asbestos. It is braided from E-glass fiber impregnated with PTFE. The packing has many excellent characteristics such as high strength, high-temperature resistance, low density, low thermal conductivity, good insulation, and non-ignitibility, etc. Glass fiber packing without any impregnation and Glass fiber packing impregnated with graphite are also available.

Glass fiber packing is ideal organic and inorganic fiber as a replacement of asbestos. It is braided from E-glass fiber impregnated with PTFE. The packing has many excellent characteristics such as high strength, high-temperature resistance, low density, low thermal conductivity, good insulation, and non-ignitibility, etc. Glass fiber packing without any impregnation and Glass fiber packing impregnated with graphite are also available. -

Kynol Fiber Packing Braided (also called GOLDEN ARAMID Packing) is a high-performance sealing material made from Kynol (Novilid or Phenolic) fibers and impregnated with PTFE lubricant. This material combines excellent mechanical properties, flexibility, and strength, making it suitable for various industrial applications.

Kynol Fiber Packing Braided (also called GOLDEN ARAMID Packing) is a high-performance sealing material made from Kynol (Novilid or Phenolic) fibers and impregnated with PTFE lubricant. This material combines excellent mechanical properties, flexibility, and strength, making it suitable for various industrial applications. -

Expanded Graphite packing is braided from low-sulfur expanded graphite yarns reinforced by cotton, glass fiber, etc. It has very low friction, and does not damage shafts or stems. It shows good thermal and chemical resistance and high elasticity. Expanded graphite packing can be reinforced with Inconel wire, SS wire, nickel wire, and other metal materials to improve mechanical strength.

Expanded Graphite packing is braided from low-sulfur expanded graphite yarns reinforced by cotton, glass fiber, etc. It has very low friction, and does not damage shafts or stems. It shows good thermal and chemical resistance and high elasticity. Expanded graphite packing can be reinforced with Inconel wire, SS wire, nickel wire, and other metal materials to improve mechanical strength. -

Ceramic fiber braided packing rope is made from high-quality ceramic fiber, it has excellent capabilities of high strength and high-temperature resistance. Ceramic fiber is a standout among the different organic and inorganic fibers as an ideal replacement of asbestos, it has excellent capabilities of high strength and high-temperature resistance. Ceramic Fiber Packing can be impregnated with graphite or insert with steel wire

Ceramic fiber braided packing rope is made from high-quality ceramic fiber, it has excellent capabilities of high strength and high-temperature resistance. Ceramic fiber is a standout among the different organic and inorganic fibers as an ideal replacement of asbestos, it has excellent capabilities of high strength and high-temperature resistance. Ceramic Fiber Packing can be impregnated with graphite or insert with steel wire -

Graphite sheet is selected from the high purity flake graphite. They can be reinforced by metal mesh, foil, or tanged metal. They are made through chemical treatment, expanded under high temperature, and then rolling. It offers excellent sealing capabilities under extreme conditions with a longer life and less maintenance.

Graphite sheet is selected from the high purity flake graphite. They can be reinforced by metal mesh, foil, or tanged metal. They are made through chemical treatment, expanded under high temperature, and then rolling. It offers excellent sealing capabilities under extreme conditions with a longer life and less maintenance. -

Fibreglass cloth is woven by continuous texturized glass fibre yarns, including C-glass and E-glass. Its woven styles include plain-woven and twill woven, according to different applications and requirements. It feels soft, smooth and compact. The surface can be foiled with aluminium or treated with silicon, vermiculite and PTFE, etc.

Fibreglass cloth is woven by continuous texturized glass fibre yarns, including C-glass and E-glass. Its woven styles include plain-woven and twill woven, according to different applications and requirements. It feels soft, smooth and compact. The surface can be foiled with aluminium or treated with silicon, vermiculite and PTFE, etc. -

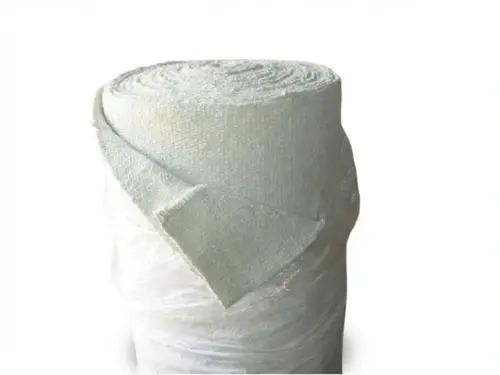

Ceramic Fiber Cloth is a woven fabric made of our high quality ceramic fiber yarns. It can be used for high temperature applications up to1000° C. The cloth is reinforced with fiberglass filament and optional stainless steel wire. It contains a certain amount of binder material which is normally burned at lower temperatures and does not affect the insulation property.

Ceramic Fiber Cloth is a woven fabric made of our high quality ceramic fiber yarns. It can be used for high temperature applications up to1000° C. The cloth is reinforced with fiberglass filament and optional stainless steel wire. It contains a certain amount of binder material which is normally burned at lower temperatures and does not affect the insulation property. -

Ceramic Fiber Tape is a woven tape made of our high-quality ceramic fiber yarns. It can be used for high-temperature applications up to 1000°C. The tape is reinforced with fibreglass filament and optional stainless steel wire. It contains a certain amount of binder material which is normally burned at lower temperatures and does not affect the insulation property.

Ceramic Fiber Tape is a woven tape made of our high-quality ceramic fiber yarns. It can be used for high-temperature applications up to 1000°C. The tape is reinforced with fibreglass filament and optional stainless steel wire. It contains a certain amount of binder material which is normally burned at lower temperatures and does not affect the insulation property. -

Ceramic fiber rope includes three types: twisted, round braided and square braided. All are made of our high-quality ceramic fiber yarns. They can be used for high-temperature applications up to 1000° C. The rope is reinforced with fibreglass filament and optional stainless steel wire. It contains a certain amount of binder material which is normally burned at lower temperatures and does not affect the insulation property.

Ceramic fiber rope includes three types: twisted, round braided and square braided. All are made of our high-quality ceramic fiber yarns. They can be used for high-temperature applications up to 1000° C. The rope is reinforced with fibreglass filament and optional stainless steel wire. It contains a certain amount of binder material which is normally burned at lower temperatures and does not affect the insulation property.